Gold Washing Plant

The gold washing plant is a kind of mechanical equipment mainly used for the separation of placer gold. The gold washing plant can be loaded manually or by the loader to the silo, and the materials are washed and screened by the trommel screen or rotary scrubber. The large particle waste is discharged, and the remaining materials are selected by the agitating chute or fixed chute.

Types of Gold Washing Plant

The wash plants have different structure types: portable/mobile, trailer-mounted, skid-mounted, and fixed mounted for easy land transportation and quick on-site installation.

Products Shows

Mobile Gold Washing Plant

The mobile/portable gold wash plant integrates ore mining and gold mineral processing operations, including the excavation system, mineral processing equipment, water supply system, tailings treatment system, power supply, etc.

The mobile gold washing plant is a kind of gold equipment that can be moved on land. It has the characteristics of compact structure, strong integrity, light-weight, large handling capacity, simple operation, reliable operation, easy maintenance, and convenient operation.

Mobile Gold Washing Plants for Sale

There are two kinds of washing plants that can be chosen for gold mining, one is the plant with a trommel screen, and the other one is with a rotary scrubber and trommel.

The following mobile gold washing plants are the piece of common suite equipment for small-scale gold mining with scalability and flexibility.

1. Mobile Gold Washing Plant With Trommel Screen (few sticky raw materials)

The mobile gold washing plant with a trommel screen is fit for a few sticky raw materials.

Screening System

Drum screen/rolling cylinder drum sieve is designed for processing minerals, mainly for alluvial/placer gold ore washing & screening. It consists of a half-covered trommel screen, one diesel engine/ electric motor, water pump & water pipes, and other facilities such as the feeding hopper and the mobile system.

The trommel screen adopts different aperture openings and various sieves to treat different raw materials, improve screening efficiency, and prolong the sieve life.

The small and portable gold wash plant with a trommel is a more flexible and cheaper gold washing solution, it can be fully customizable & moveable. This small machine can be equipped with a sluice box, gold centrifugal concentrator, shaker table, gold trommel, and another washer, like the sand washing machine. Also, vibrating feeders, vibrating screens, pumps, and other portable mining equipment can be used according to different conditions.

Mobile Gold Washing Plant With Trommel Features

- Configured for economical & efficient classification, screening, and grading.

- Heavy-duty trommel drum with lifters at the front to facilitate material break up.

- Screen replaceable for different mesh sizes.

- Multiple screen sizes.

- Easily changed screen plates.

- Largest processing capacity in the industry.

- Unique screen design results in higher capacities, longer screen life, and no material clogging.

- Heavy-duty feed hopper and extension.

- Discharge chute

- Gear drive mechanism

- Variable speed drive mechanism

Configuration Parameter

| Machine | Model | Capacity | Feeding Size |

| Gold Washing Trommel | JXSC-900 | 40 tons per hour | 150-200mm |

| Gold Centrifugal Concentration | STLB60 | 8-12 tons per hour | 3mm |

| Sluice Box | 1*6 m | 20 tons per hour | 3-15mm |

| Shaking Table | LY2100 | 500 kg per hour | 2mm |

2. Mobile Gold Washing Plant With Rotary Scrubber (sticky raw materials)

The mobile gold washing plant with a rotary scrubber is fit for sticky raw materials, such as clay, laterite, and kaolin.

Clay Processing System

- With customized capacity and strong power scrubbing, a large capacity can reach 200-250tons per hour.

- The long washing drum of the scrubber retains material for longer, more vigorous washing for complete separation.

- One high-output electrical motor is driving a rubber wheel system, providing efficient torque.

- Rotation speed can be adjusted by the advanced reducer.

- The water with high pressure flushed the inside of the drum.

- Can accept material up to 230mm.

Features

- Designed to break up alluvial gravels, clays, and sand.

- High capacity and high power scrubbing.

- The long drum of the scrubber retains material for longer, more vigorous washing for complete separation.

- Thickening type steel plate for the drum.

- Heavy-duty bearing, gear, and roller.

- Wearable screen at the exit of the drum for screening.

- One high output electrical motor driving a gear system provides efficient torque.

- The water with high pressure flushed the inwall of the drum.

- Can accept material up to 230mm.

- Shell design less mass than conventional roller supported units – installation craneage requirement reduced the rotary drum.

Advantages

- The use cost of a drum ore washer is low, and the single processing capacity can be up to 200 t/h. The mineral washed out contains less than 0.5% mud and less than 2 % water. The impeller drive bearing device is isolated from water and water materials, which can avoid damage to the bearing due to water, sand, and pollutants.

- The ore is fully soaked in the front end of the drum ore washer, and the separation of ore and mud is realized at the back end. The water-saving effect of the whole set of equipment is remarkable; the washing efficiency is up to 98%. Two or three different specifications of sand and stone products can be obtained by installing a single or double-layer circular screen in the rotary drum.

Gold Washing Plant Process

Feeding: Dredge pump, hopper feeder with vibrating grizzly bar.

Washing and Screening: Usually use a rotary scrubber, gold trommel, sand washing machine, vibrating screen, etc.

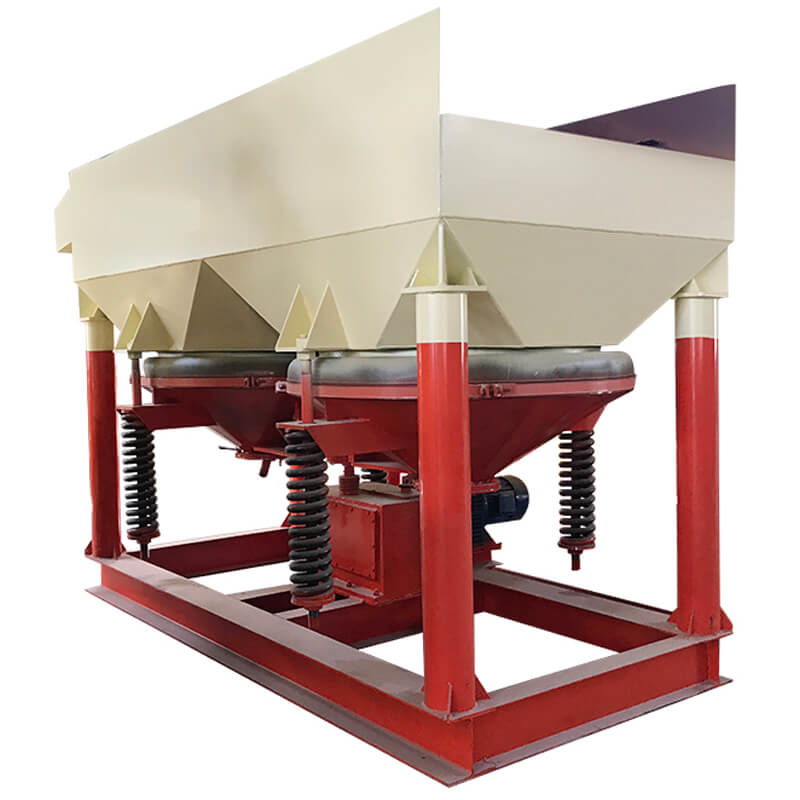

Beneficiation: Gold centrifugal concentrator, shaker table, sluice box, mineral jig.

Water supply

Tailings

Mobile System: Composed of chassis and traction steering, two major components, 4 axes 16 tires, 4 mechanical legs support centrifuge, can be turned in situ 180 degrees, easy to move to the workplace.

According to the size of free gold, different equipment such as jig, centrifugal concentrator, sluice box, or shaker table is equipped to the wash plant to recover coarse and fine free gold fully. The recovery rate is up to 97%.

Mobile Gold Washing Plant Power Selection

The customer can select the electric grid or the diesel generator to supply power to the electric motors of the mobile washing plant.