Home » Equipment » Crushing & Screening Equipment » Hammer Crusher

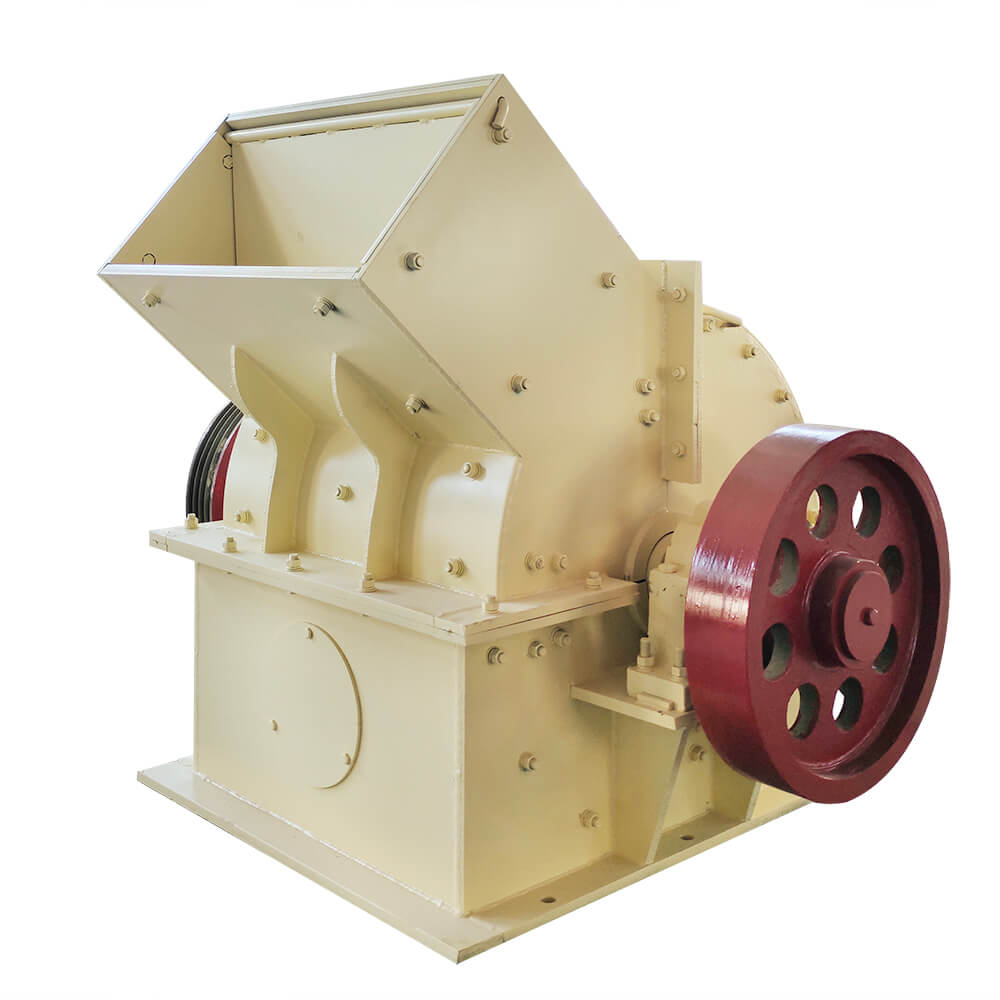

Hammer Crusher

Hammer crusher is a kind of equipment that crushes materials by impacting them with its high-speed rotating hammer head. It is widely used in the crushing and grinding of materials in the mining, building materials, chemical, electric power, and other industries. It is particularly suitable for crushing brittle materials (such as coal, limestone, gypsum, etc.).

Capacity: 1-110 tph

Feeding Size: ≤350 mm

Discharge Size: 0-35 mm

Process Material: Cement, coal, white subdivision, gypsum, alum, brick, tile, limestone, and other soft-medium hardness materials.

Hammer Crusher Overview

A hammer mill is a rock crusher used in various industries to reduce the size of materials, such as limestone, coal, slags, gypsum, and glass. It uses of high-speed rotary hammer to impact the ore. The finished product size is adjustable by controlling the grate openings, rotor speed, hammer capacity, etc. Hammer mill, same as hammer crusher, hammer breaker, can crush the 600-1800mm to below 25 mm. Sometimes, the hammer mill crusher is named by the application fields, such as coal crusher, coke crusher, limestone hammer crusher, brick crusher, cement hammer crusher, etc.

Hammer Crusher Types

- Single rotor and double rotary hammer crusher

- Directional and reversible hammer crusher

- Vertical shaft, ring hammer crusher, swing hammer crusher

- Fixed and mobile hammer crusher

Advantages

Hammer Crusher Advantages

The hammer crusher is designed for easy adjustment of product size, providing high grinding capability for efficient material processing. Its design ensures stable operation and facilitates simple maintenance with quick exchange of worn parts, minimizing downtime. Constructed with hammers made from a durable chromium alloy containing 20% to 27% chromium, this crusher delivers exceptional performance and longevity. Pricing for hammer crushers varies based on capacity and base materials; however, JXSC specializes in tailor-made configurations to meet diverse working requirements, ensuring longer service life and reduced maintenance. Contact us for the best stone hammer crusher machine price tailored to your needs.

✔ Versatility: Can be used for coarse, medium, and fine crushing, and can handle materials of various hardness.

✔ High crushing ratio: Strong breaking capacity, crushing ratio can reach 50:1, and the particle size of the material can be adjusted.

✔ Easy to operate: Simple structure, stable operation, easy maintenance, and replacement of parts.

✔ Lower energy consumption: Compared with similar equipment, the hammer crusher has lower energy consumption.

✔ Economical and applicable: Relatively small equipment investment, low overall operating cost.

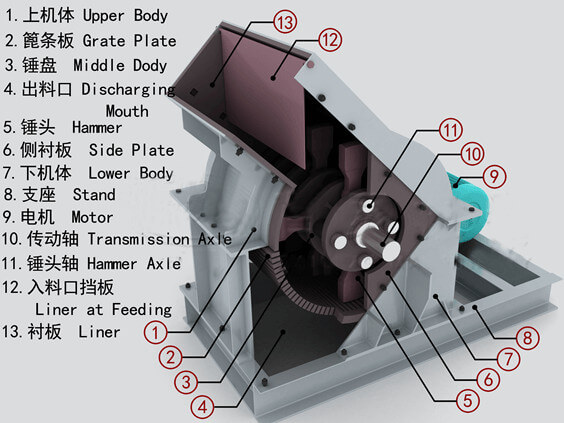

Structures & Working Principle

Hammer Crusher Structure

The main parts of a hammer crusher are the crushing chamber, rotor shaft, frame, impact hammer, grate bars, motor, flywheel, grate, pallets and lining, dust seal, and overload protection device.

Hammer Crusher Working Principle

Material is fed into the hammer crusher, which is subject to rotation, high-speed impact, and collision. Qualified crushed ore is discharged through the grate, the larger size materials continue to be crushed and shattered until they reach the required size.

Technical Parameters

| Model | Feeding Size (mm) | Discharge Particle Size(mm) | Capacity (t/h) | Power (kw) |

| PCS300*200 | <60 | <10 | 1-2 | 7.5 |

| PCS400*300 | <80 | <10 | 1-3 | 7.5 |

| PC400×300 | <100 | <15 | 3-10 | 11 |

| PC600×400 | <150 | <15 | 10-20 | 22 |

| PC800×600 | <200 | <25 | 20-50 | 55 |

| PC1000*800 | <350 | <35 | 50-70 | 75-90 |

| PC1000×1000 | <350 | <35 | 70-90 | 90-110 |

| PC1200*1200 | <350 | <35 | 80-110 | 132-160 |