Home » Equipment » Dewatering Equipment » Rotary Dryer

Rotary Dryer

Rotary dryer is a high-efficiency continuous drying equipment widely used in chemical, metallurgy, building materials, food, and other fields. It is especially suitable for processing granular, powdery, and paste materials.

Capacity: 1.9~76 T/H

Procession Material: Gold, chrome, tin, coltan, diamond, tantalum, silica sand

Rotary Dryer Overview

The rotary dryer can be used for drying materials with a certain humidity or granularity, widely used in building materials, metallurgy, chemical industry, cement industry drying slag, limestone, sludge, slag, clay, and other materials.

The drum dryer has strong adaptability to materials, can dry all kinds of materials, and the equipment operation is simple and reliable, so it has been widely used.

Advantages

The rotary dryer offers exceptional drying performance through its compact yet efficient design, requiring minimal floor space while delivering reliable operation with significantly low energy consumption. Its high heat efficiency ensures optimal drying results, consistently producing quality output across various materials. The system’s simplified automation allows for easy control with minimal operator intervention, making it both a cost-effective and labor-efficient solution for industrial drying applications. This combination of space-saving design, energy efficiency, and automation-friendly features makes the rotary dryer an ideal choice for processing plants prioritizing productivity and operational economy.

✔ Highly adaptable

Can handle materials in various forms, including granules, powders, pastes, and filter cakes.

✔ High processing capacity

A single unit can evaporate more than 10 t/h of water.

✔ Stable operation

Continuous operation with mature automated control.

✔ Flexible heat source

Suitable for multiple heat sources, including coal, gas, steam, and waste heat.

✔ High thermal efficiency

Combined with a waste heat recovery system, thermal utilization exceeds 70%.

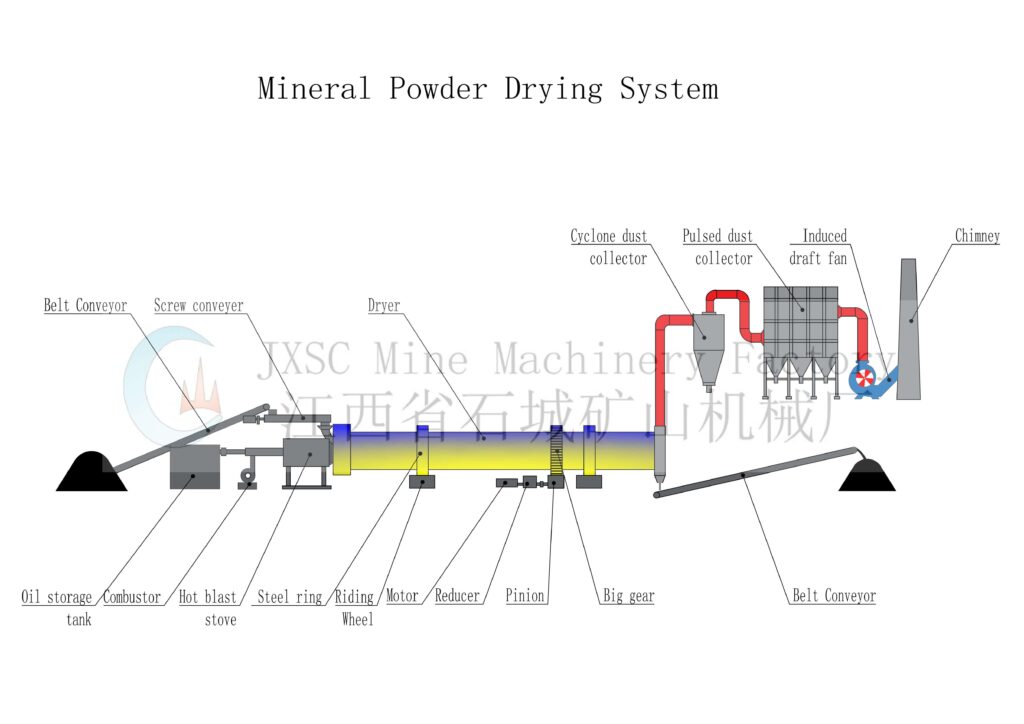

Structures & Working Principle

Rotary Dryer Structure

The rotary drum dryer is mainly composed of rotary body, lifting plate, transmission device, supporting device and sealing ring and other parts.

Rotary Dryer Working Principle

The mineral material is transported to the hopper by a belt conveyor or bucket elevator, and then the hopper feeder enters the feeding end through the feeding pipe. The inclination of the feeding pipe should be greater than the natural inclination angle of the material so that the material can flow smoothly into the mine dryer. The dryer cylinder is a rotating cylinder tilted slightly to the horizontal line. The material is added from the higher end, and the heat-carrying body enters from the lower end. The heat-carrying body is in contact with the material in a countercurrent way. As the cylinder rotates, the material is moved to the lower end by gravity. In the process of moving forward in the cylinder, the wet material is directly or indirectly given the heat carrier, which makes the wet material dry, and then is sent out through the belt conveyor or the screw conveyor at the discharging end. The inside wall of the slag dryer is equipped with a copy board, which can copy and scatter the material, so as to increase the contact surface between the material and the airflow, so as to increase the drying rate, and promote the advancement of the material. After the heat carrier Dryer, the general need for the cyclone dust collector gas with the material captured down.

Technical Parameters

| Model Diameter*Length | Drum Volume(m3) | Capacity(t/h) | Angle of Inclination(%) | Intake Humidity(℃) | Main Motor(kW) | Weight(t) |

| Ⴔ1.2×8 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Ⴔ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Ⴔ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Ⴔ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Ⴔ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Ⴔ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Ⴔ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Ⴔ2.2×14 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Ⴔ2.2×18 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Ⴔ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Ⴔ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Ⴔ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Ⴔ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Ⴔ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Ⴔ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Ⴔ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Ⴔ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Ⴔ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Ⴔ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |