Home » Equipment » Washing Equipment » Rotary Scrubber

Rotary Scrubber

The rotary scrubber is a widely used mineral washing machine in industries such as mining, construction materials, and metallurgy. It is primarily designed to remove clay, silt, and other impurities from ore surfaces, thereby improving the ore grade and serving as a pre-treatment for subsequent crushing and separation processes.

Capacity: 1-400 TPH

Process Material: Gold dredger, quartz mine, limonite ore, nonferrous ore, construction use sand and gravel washing, etc.

Rotary Scrubber Overview

Gold trommel scrubber, also known as rotary screen ore washer, or cylinder screen washer. It is a multi-purpose hydraulic cleaning and soil removal equipment that serves both cleaning and screening functions. That is, the trommel scrubber machine cannot only preliminary clean the raw materials but also sieve them by particle.

The trommel washing machine is placed before a crusher, gravity separator, magnetic separator, and flotation to avoid clogging and improve beneficiation efficiency.

Rotary Scrubber Types

JXSC supplies two types of gold trommel scrubber machines: the fixed type rotary scrubber and mobile rotary scrubber.

Our Rotary Scrubber for Sale

- Screen Mesh: Mesh size 8 – 50mm.

- Screen Material: PU or manganese or stainless steel, 1 layer, 2 layers.

- Liner Plate: Natural rubber, spiral welded steel plate.

Advantages

Rotary scrubbers offer significant advantages with their trommel design that effectively combines washing and screening functions, delivering high production capacities ranging from 1 to 250 tons per hour while maintaining low operating costs, easy maintenance, and quiet operation. These versatile machines feature fully customizable specifications including drum length/diameter, screen mesh configuration, layer counts, liner plates, mobility options (portable or stationary), and drive tire materials to suit various applications – from small-scale gold wash plants to mini gold trommel operations. The system’s efficient washing is further enhanced by internal water spray pipes and smooth rubber-tired drive mechanisms for reliable performance.

✔ High Efficiency: Removes >80% of sludge, ideal for clay-rich ores.

✔ Robust Structure: Easy maintenance with wear-resistant linings for extended service life.

✔ Multifunctional: Combines washing, grading, and de-sliming, reducing downstream processing load.

✔ Wide Adaptability: Suitable for various ores (gold, iron, tungsten, etc.) and production scales.

Structures & Working Principle

Rotary Scrubber Structure

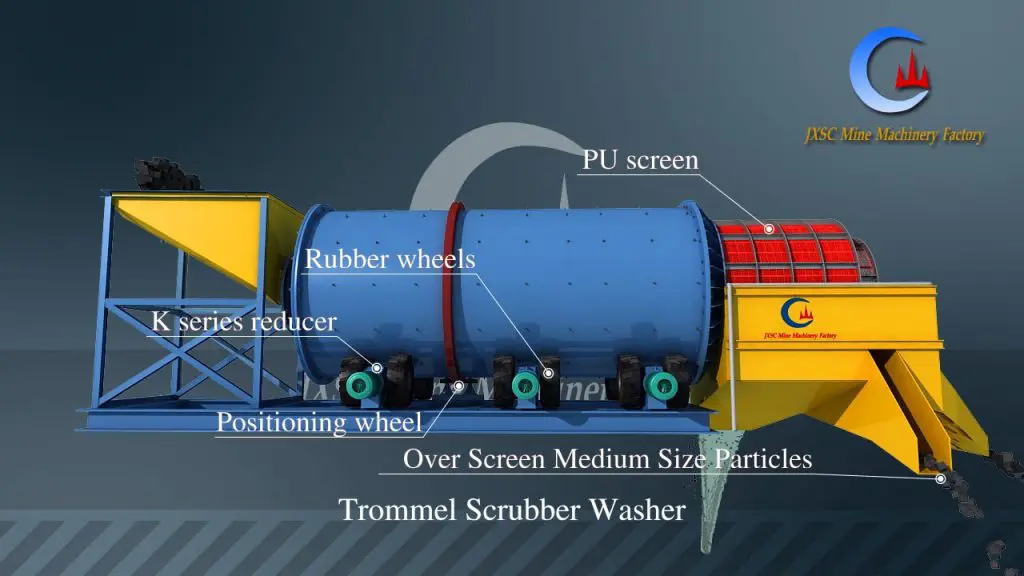

Trommel scrubber washer machine with two parts: drum scrubber and screen. The drum scrubber is for washing ore, the screen is for sieving different size particles after washing.

Rotary Scrubber Working Principle

A high-pressure flushing water pipe is arranged in the longitudinal direction of the cylinder. The rotation of the cylinder screen causes the ore to turn over and collide with each other, and with the hydraulic scouring, the clay is broken and cleaned.

The washing effect increases with the residence time of the ore in the return screen, the water pressure of the spray water, and the water consumption. In order to strengthen the mechanical action of the equipment, longitudinal steel bars for loose ore can be installed on the inner wall of the cylindrical sieve.

Technical Parameters

| Model | Drum Dia (mm) | Drum & Screen Length (m) | Screen Mesh Size (mm) | Rotation Speed (r/min) | Feeding Size (mm) | Angle of Inclination(°) | Capacity (t/h) | Power (kW) |

| JXSC-400 | 400 | 2m+1.2m | ≤20 | 27.9 | ≤80 | ≤10 | 1-5 | 3 |

| JXSC-600 | 600 | 2m+1.2m | ≤25 | 27.6 | ≤80 | ≤10 | 5-10 | 4 |

| JXSC-750 | 750 | 2.5m+1.5m | ≤25 | 27.6 | ≤100 | ≤10 | 10-20 | 5 |

| JXSC-900 | 900 | 3m+1.8m | ≤25 | 27.6 | ≤100 | ≤10 | 20-40 | 11 |

| JXSC-1200 | 1200 | 4m+2m | ≤25 | 17 | ≤100 | ≤10 | 40-70 | 15 |

| JXSC-1500 | 1500 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 70-100 | 30 |

| JXSC-1800 | 1800 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 100-150 | 18.5*2 |

| JXSC-2100 | 2100 | 4m+2m | ≤50 | 16 | ≤1000 | ≤10 | 150-200 | 22*2 |

| JXSC-2400 | 2400 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 200-250 | 22*4 |

| JXSC-2700 | 2700 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 250-270 | 55*2 |

| JXSC-3000 | 3000 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 270-300 | 30*4 |

| JXSC-3200 | 3200 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 300-340 | 37*4 |

| JXSC-3400 | 3400 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 340-370 | 45*4 |

| JXSC-3600 | 3600 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 370-400 | 55*4 |