Home » Equipment » Gravity Separation Equipment » Shaker Table

Shaker Table

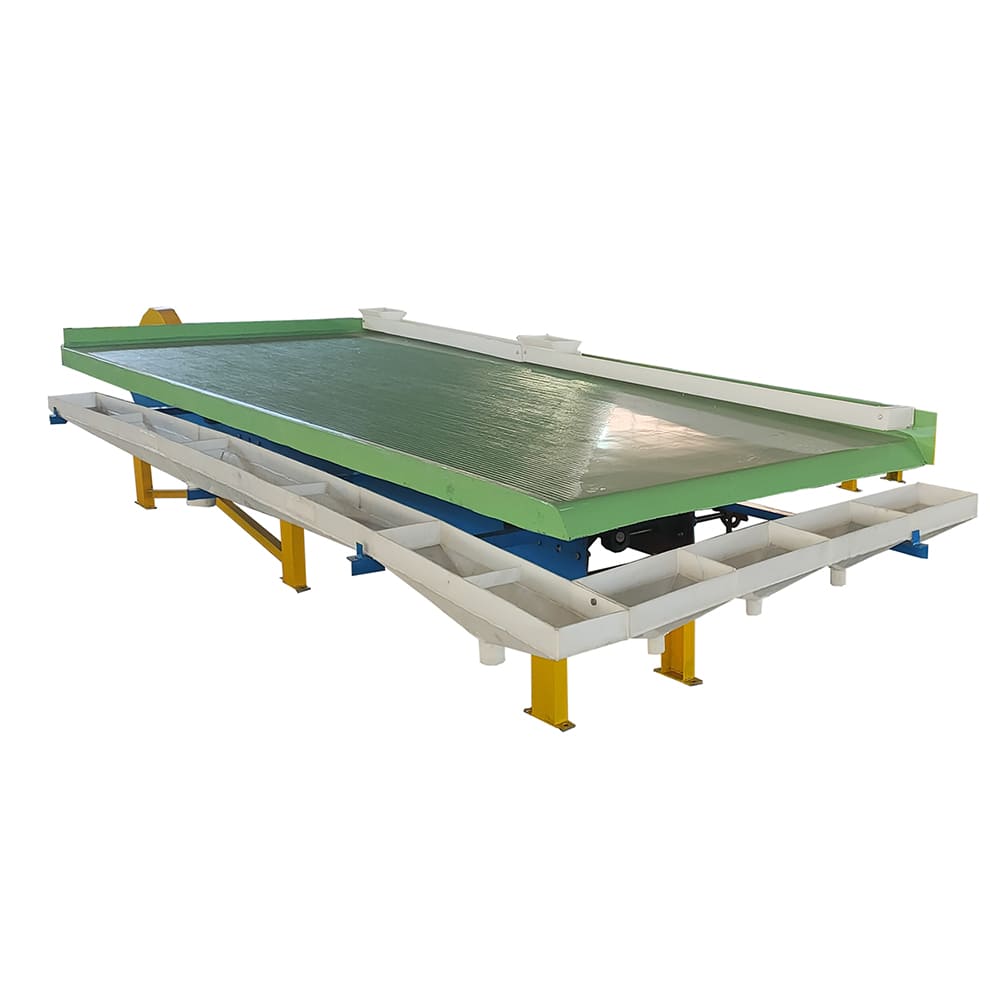

The shaker table is a gravity ore dressing equipment that uses mechanical vibration and thin layer water flow to achieve mineral classification. It is a typical flow film ore dressing machine and is widely used in processing metal and non-metallic minerals with a particle size of 0.037-2mm.

Capacity: 0-2 T/H

Feeding Size: 0-2mm

Feeding Density: 15%-30%

Process Material: Gold, tin, tungsten, lead, manganese, tantalum, chrome, and so on precious metals, and nonferrous metals.

Shaker Table Overview

A shaker table is also known as a gold shaking table, gold separation table, or concentrating table. It is a fine gold recovery equipment common in the gold shaker wash plant, alluvial gold mining plant to separate concentrates, medium concentrates, and tailings according to material density and grain size.

Gold mining shaker table can not only be used as an independent beneficiation machine, but it often works with jig separator machines, centrifugal concentrators, sluice boxes, flotation equipment, magnetic drum separator, spiral classifier, and other ore dressing equipment.

Shaker Table Types

- Seated table and suspended table

- Single-layer shaker and multi-layer shaker

- Coarse particle (2~0.5mm), fine gold (0.5~0.2mm)

- RP4 shaker table, 6-s shaker

- Industrial shaker table, mini gold shaker table, lab shaker table, portable shaker table

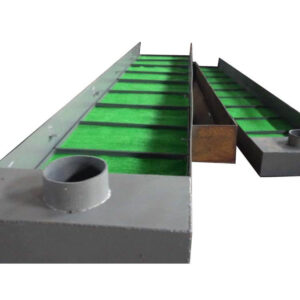

Table Surface Materials

Glass-reinforced plastics (glass fiber reinforced polyester resin) and aluminum alloy (laboratory use).

Advantages

Shaker Table Advantages

The shaker table offers high separation efficiency, effectively recovering gold concentrate while simultaneously discharging tailings in a single process. Designed for easy installation, operation, and maintenance, it ensures a user-friendly experience with minimal downtime. Performance can be fine-tuned with adjustable stroke length and speed, allowing operators to optimize recovery for different feed conditions. With low upfront costs, long service life, and minimal maintenance requirements, it delivers an excellent return on investment. Additionally, its compact and portable design makes it an ideal solution for small-scale operations, field testing, and mobile processing plants.

✔ Precise sorting: can sort out more than 6 product grades.

✔ Low energy consumption: single unit power is only 1.1-2.2kW.

✔ Visual adjustment: the bed surface is visible and easy to adjust in real time.

✔ Strong adaptability: maintains good selectivity when processing 0.1mm materials.

Structures & Working Principle

Shaker Table Structure

The main parts of a shaking table are head, electric motor, slope regulator, ore tank, water tank, compound strip, and lubrication system.

Shaking Table Working Principle

Shaking table mineral separation is an inclined table, the combined action of the symmetrical reciprocating motion of a mechanical slab and the flow of water on a thin inclined plane, causes loose layering and zoning of ore particles on the table surface, thereby causing the mineral separation process to be carried out according to different densities.

Technical Parameters

| Deck type | Unit | Course sand | Fine sand | Slime Deck | Three different kinds of decks are available | |||

| Beneficiation Area | m2 | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | |

| Deck Size | Length | mm | 4450 | 4450 | 4450 | 3000 | 2100 | 1100 |

| transmission end width | mm | 1855 | 1855 | 1855 | 1320 | 1050 | 500 | |

| Concentrate end width | mm | 1546 | 1546 | 1546 | 1100 | 850 | 430 | |

| Maximum Feeding Size | mm | 2 | 0.5 | 0.15 | 0.1-2 | 0.074-2 | 0.074-2 | |

| Process Capacity | t/h | 1.5-2 | 0.8-1.5 | 0.5-0.8 | 0.4-1.5 | 0.3-0.8 | 0.05-0.2 | |

| Feeding Density | % | 25-30 | 20-25 | 15-25 | 10-30 | |||

| Stroke | mm | 16-22 | 11-16 | 8-16 | 6-30 | 12-28 | 9-17 | |

| Frequency | f | 45-48 | 18-53 | 50-57 | 210-320 | 250-450 | 280-460 | |

| Water added | t/d | 80-150 | 30-60 | 10-17 | 0.3-1.5t/h | 0.2-1t/h | 0.1-0.5t/h | |

| Transverse slope of Deck | ° | 2° 30-4° 30 | 1° 30-3° 30 | 1° -2° | 0 -10° | 0 -8° | 0 -10° | |

| Longitudinal slope of Deck | ° | 1.4 | 1.4 | 0.92 | —— | —— | —— | |

| Cross-section Shape of Deck | rectangular | saw tooth | triangle | Avaliable rectangular, saw tooth, triangle | ||||

| Motor Power | KW | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |