Chrome Washing Plant

- Maximize Your Chrome Recovery Rate

Comprehensive Chrome Washing Plant Solutions Tailored to Your Needs

At JXSC, we supply complete chrome processing plants designed for maximum efficiency and profitability—whether you’re treating ROM ore, tailings dumps, or fine chrome concentrates.

Your Challenges ➞ Our Solutions

Challenge or Pain

“High Clay Content”

Our Solution

“Special Scrubber With Grinding Teeth”

Challenge or Pain

“Low Recovery Rate”

Our Solution

“Custom-designed Beneficiation Chutes”

Challenge or Pain

“Frequent Breakdowns”

Our Solution

“Heavy-duty Construction For Abrasive Ores”

Challenge or Pain

“High Operating Costs”

Our Solution

“Energy-saving Designs With 30% Less Power”

Your success hinges on plant reliability and recovery rates. That’s why we engineer cost-effective yet heavy-duty plants built to endure harsh, abrasive conditions without compromising performance.

Our Solutions Cover Every Stage:

- Pre-concentration: Upgrade ROM ore early to cut downstream costs.

- Tailings retreatment: Extract value from waste with specialized gravity separation.

- Chrome wash-plants: Achieve high-grade concentrates with optimized scrubbing, screening, and spiral/jig recovery.

How Our Chrome Wash Plants Work?

Grid screen blocks oversized rocks

Clay Scrubbing

Special teeth dissociate ore particles

Precise Separation

Multi-stage chute beneficiation

Quality Output

Shaker tables for final concentrate

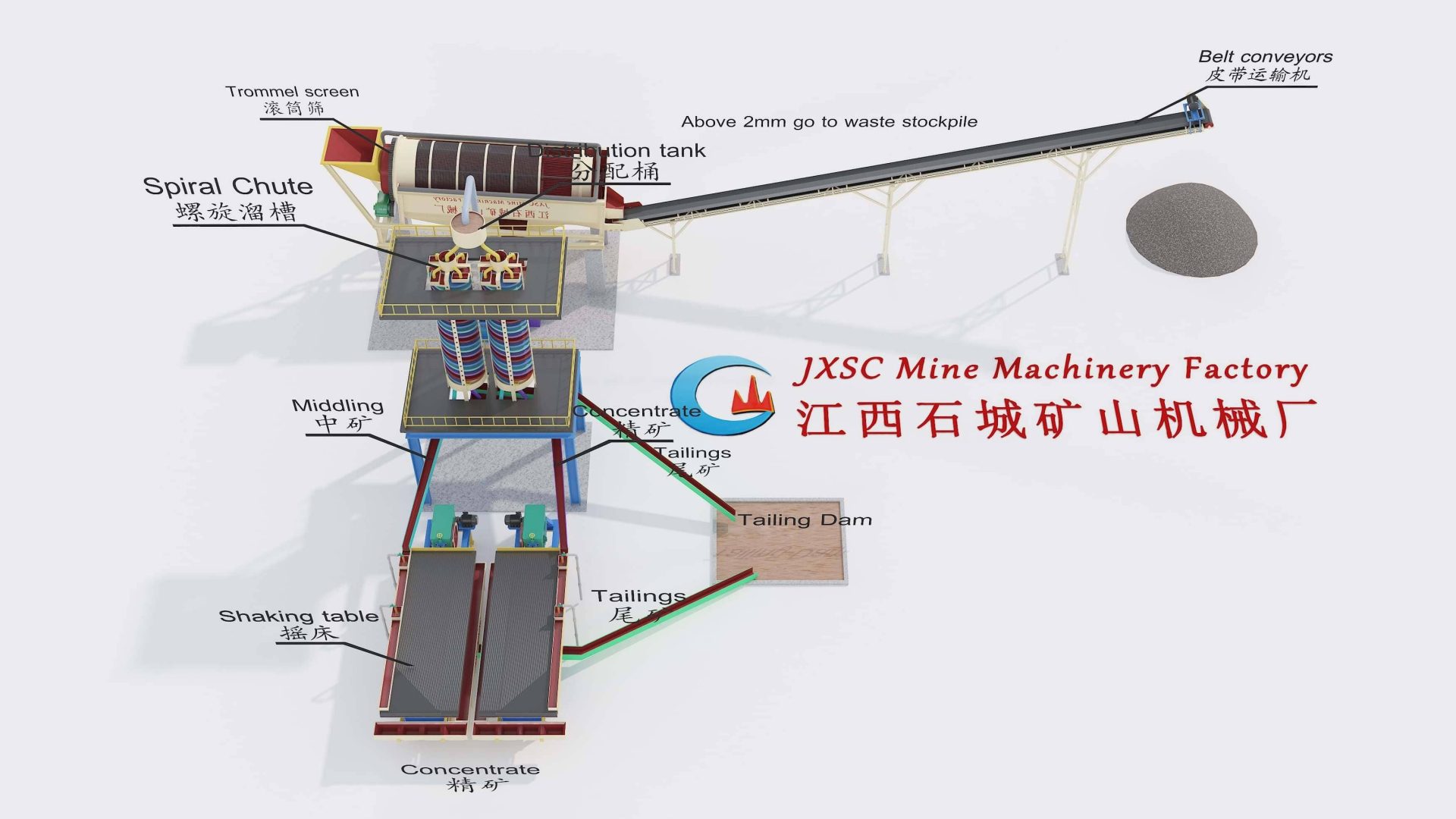

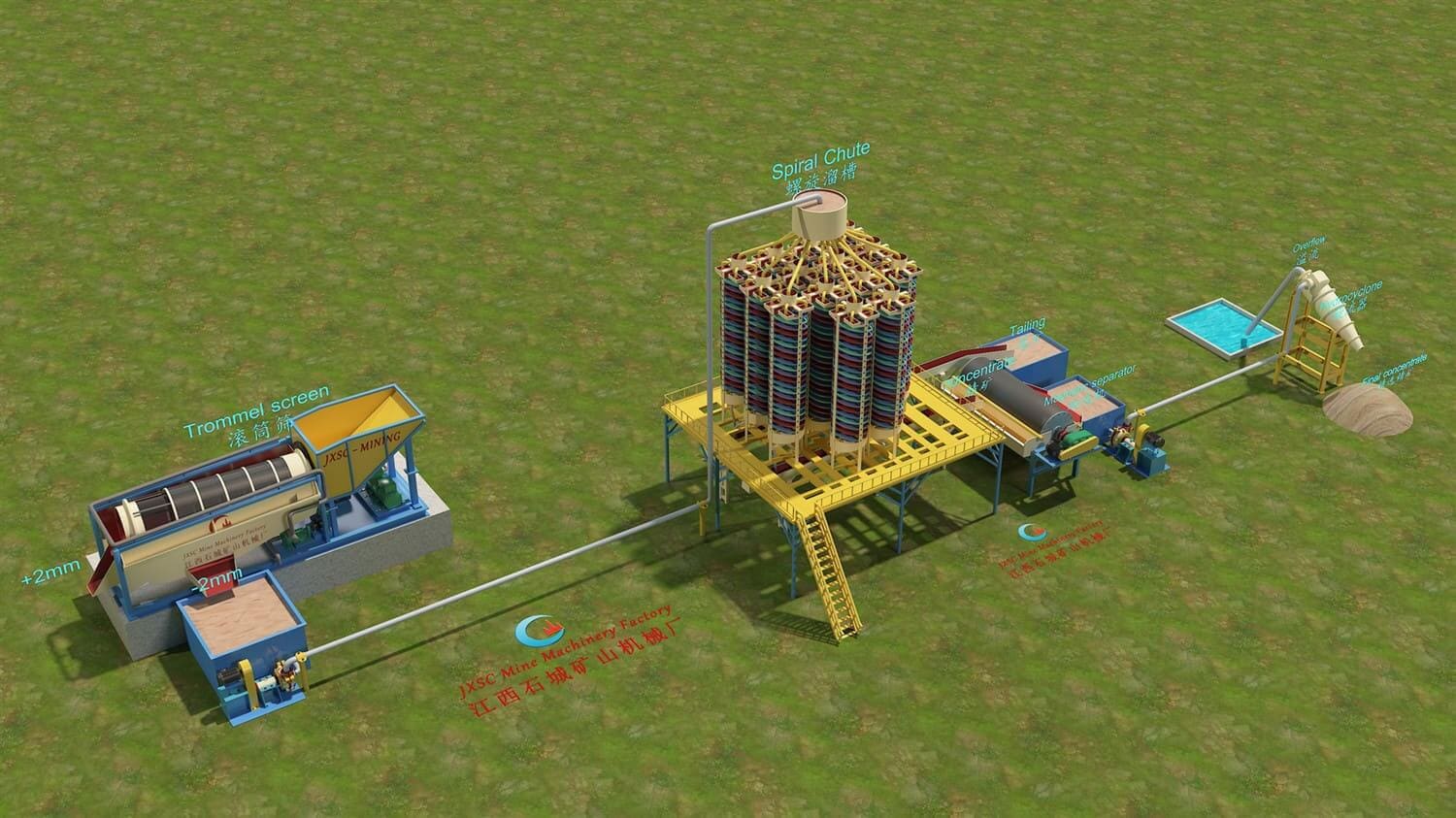

5 TPH Chrome Washing Plant Flowchart Explanation

This is a simple alluvial chrome washing plant. The main mining process is feeding, washing, and gravity separation.

The trommel screen is a kind of ore washing and screening equipment with a screen hole size of 2 mm. It can screen out waste sand larger than 2 mm and transport it away through a belt conveyor.

The undersized material (less than 2 mm) will be sent to the gravity separation device through a slurry pump.

A spiral chute is a gravity concentration machine that can separate heavy chrome from other light minerals. It has a large processing capacity and a perfect separation effect.

In this process, we use one-stage spiral chute separators. The concentrate from the spirals is sent to one shaking table, the middling is sent to another shaking table for further processing, and then it can produce a higher-grade concentrate.

All the tailings will go to the tailing dam.

Chrome Washing Plant For Sale

Chrome washing plants, or beneficiation plants, utilize various separation methods tailored to the ore’s characteristics. Common types include gravity separation plants, dense medium separation (DMS) plants, flotation plants, and magnetic separation plants. Many modern facilities combine these methods (e.g., gravity + magnetic separation) for optimal recovery. Mobile plants, equipped with trommels and spiral separators, cater to small-scale or remote operations. The choice depends on ore type, particle size, and desired concentrate grade.

Chrome Washing Plant Solutions by JXSC

Suitable for both alluvial (placer) and hard rock (lode) chrome deposits, JXSC’s plants optimize recovery rates while minimizing operational costs.

Chrome Gravity Separation

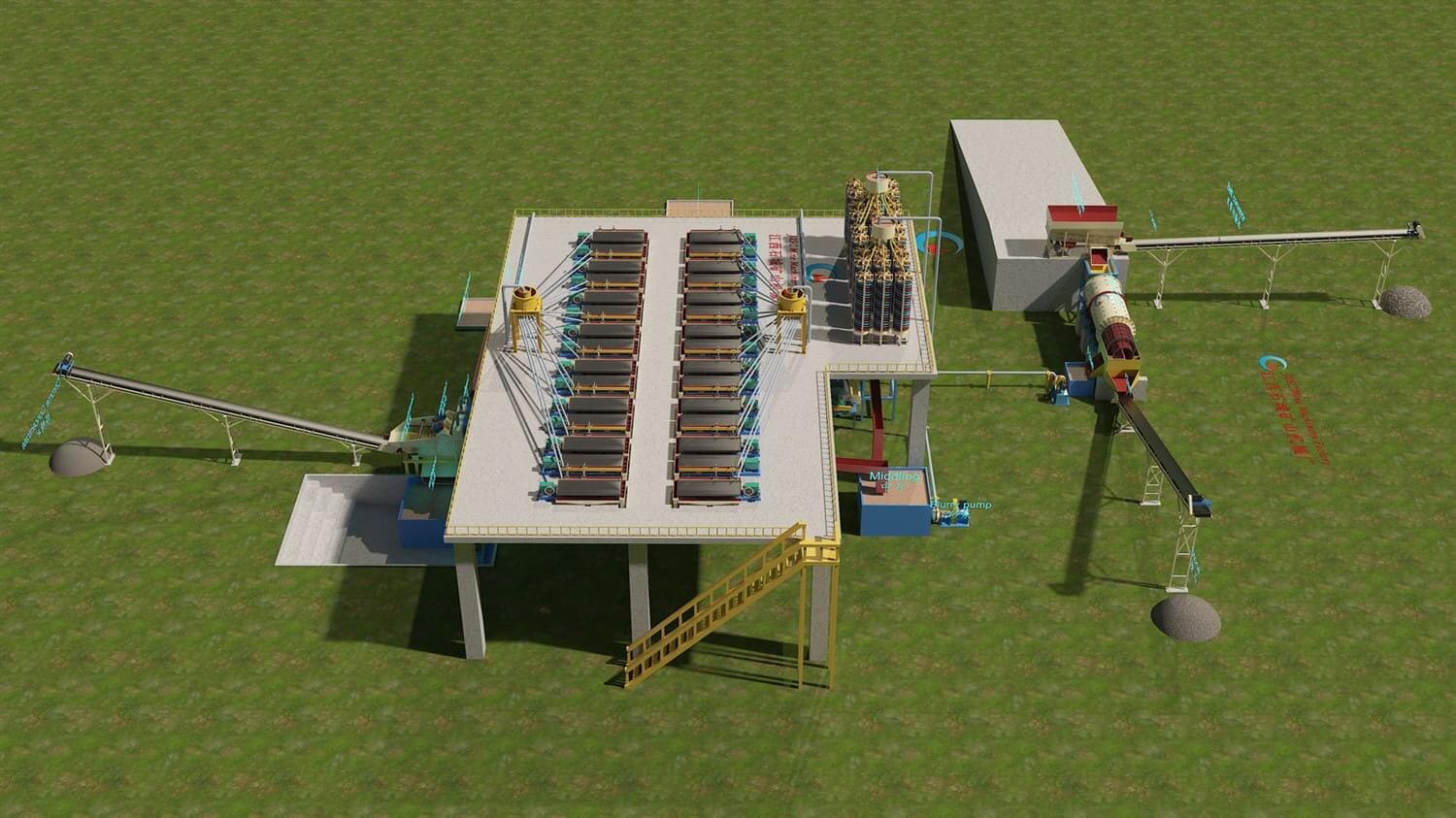

Spiral Chute + Shaker Table Plant

Raw Ore:

- Alluvial chrome ore with mostly soil and clay, mixed with some stones, gravels, and leaf branches.

- Chrome concentrate size: -2 mm.

- -2mm material accounts for 40-50% in raw ore.

- Chrome grade in raw material is 17-23%.

- The required target grade after the beneficiation process should be 48-50%.

Capacity: 100 TPH

Equipment: Vibrating Feeder, Rotary Scrubber, Spiral Chutes, Shaker Tables, Slurry Pump, Vibrating Screen, and Bely Conveyors.

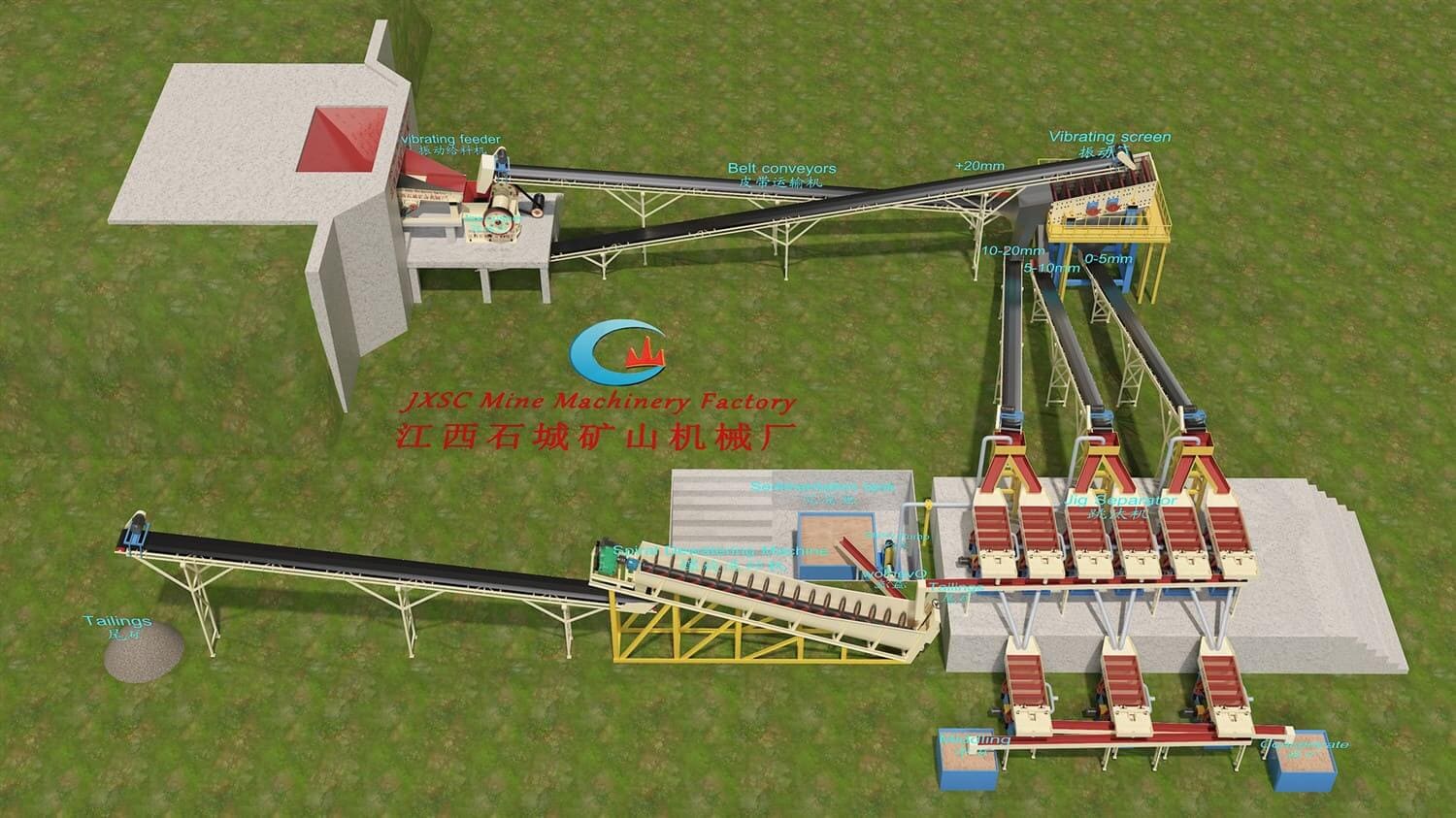

Chrome Gravity Separation

Jig Plant

Raw Ore: Ferrochrome Slag

Capacity: 100 TPH

Equipment: Vibrating Feeder, Jaw Crusher, Vibrating Screen, Spiral Sand Washer, Jig Concentrators, and Conveyors.

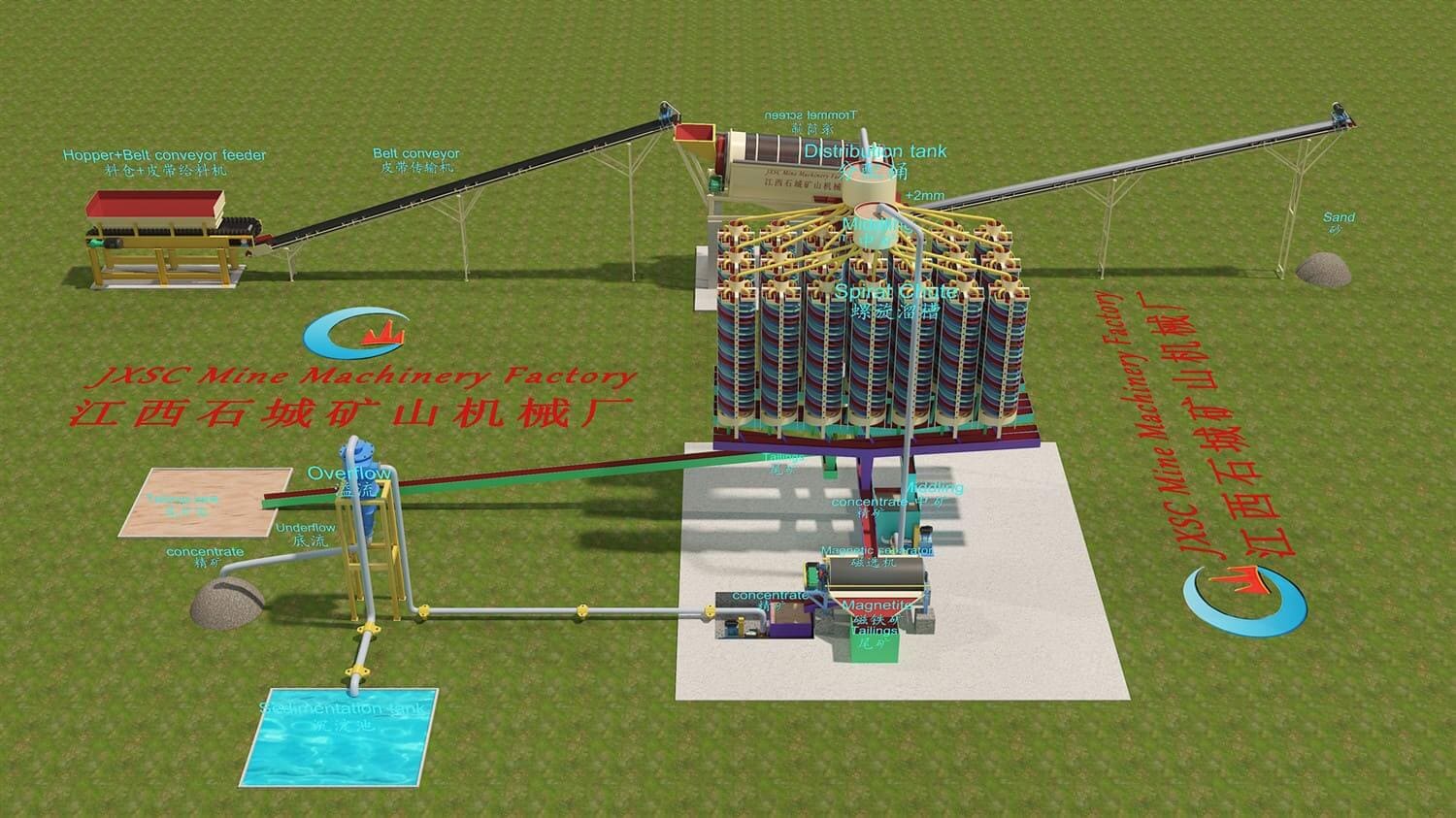

Hybrid or Combined-process Plants

Many modern chrome washing operations use a combination of these technologies to maximize recovery and efficiency. A common process flow, for example, is to use a trommel scrubber to wash the ore, a spiral concentrator for initial gravity separation, followed by a magnetic separator for further purification.

Raw Ore:

- The maximum feeding size of ROM is 50mm.

- Alluvial chrome ore, soil type without sticky clay, and the presence of magnetic iron ore in ROM.

- Chrome concentrate size is 0-2mm.

- Average chrome grade in ROM is 25-27%.

- Target chrome concentrate grade is 48%.

Capacity: 50 TPH

Equipment: Trommel Screen, Spiral Chutes, Magnetic Separators, Hydrocyclone, Slurry Pumps.

Chrome DMS Plant

Would you like details on a specific component (e.g., spiral chute selection) or a case study? Don’t hesitate to contact us!

We offer a variety of chrome washing plants for sale, including customized options based on ore type and capacity. We specialize in providing complete, customized chrome ore beneficiation solutions for both alluvial (placer) and hard rock deposits. For smaller operations or remote locations, JXSC offers mobile and modular chrome washing plants that are transportable and easy to set up.

Why Choose Us ?

✅ 40+ years of experience in mineral processing.

✅ ISO-certified manufacturing with strict quality control.

✅ Localized service centers in key mining countries.

Advantages of Our Solution

- High Recovery Rate: Efficient gravity separation ensures >90% recovery for liberated chromite.

- Modular Design: Plants can be customized (stationary or mobile) for small to large-scale operations.

- Low Operating Cost: Minimal chemical use, water recycling systems, and energy-saving equipment.

- Adaptability: Handles both high-grade and low-grade ores, including friable or clay-rich deposits.

Turnkey Services

We offer end-to-end support, including:

- Ore testing & process design (flowchart optimization).

- Equipment manufacturing & logistics (shipped globally).

- Installation & commissioning (on-site technician support).

- Training & after-sales service (remote troubleshooting, spare parts supply).

For specific project requirements (e.g., capacity, ore type), JXSC provides lab-scale testing and free technical consultation. Contact our team for tailored solutions!

Our Chrome Processing Plant Projects

Ready to Optimize Your Chrome Washing Plant?

Leave your requirements and let our engineers design the mineral processing process and select the most suitable mining equipment for you.