Blogs Related Mining Equipment, Projects & Process Plants

Kaolin Magnetic Separator And Equipment Repair

Among the development of many mining machinery industries, the kaolin magnetic separator exists as a special example, and it has maintained a good momentum of development in such a fierce market environment. Its role cannot be replaced by any equipment. In the mining, energy, transportation construction, and industrial raw materials

Problems and Solutions for Gold Flotation Machine

Flotation machine is the abbreviation of flotation mineral processing equipment. As one of the common separation equipment in chemical mineral processing, it mainly cooperates with flotation reagents to allow the slurry to achieve mineral separation with the help of the buoyancy of bubbles. There are many types of flotation machines,

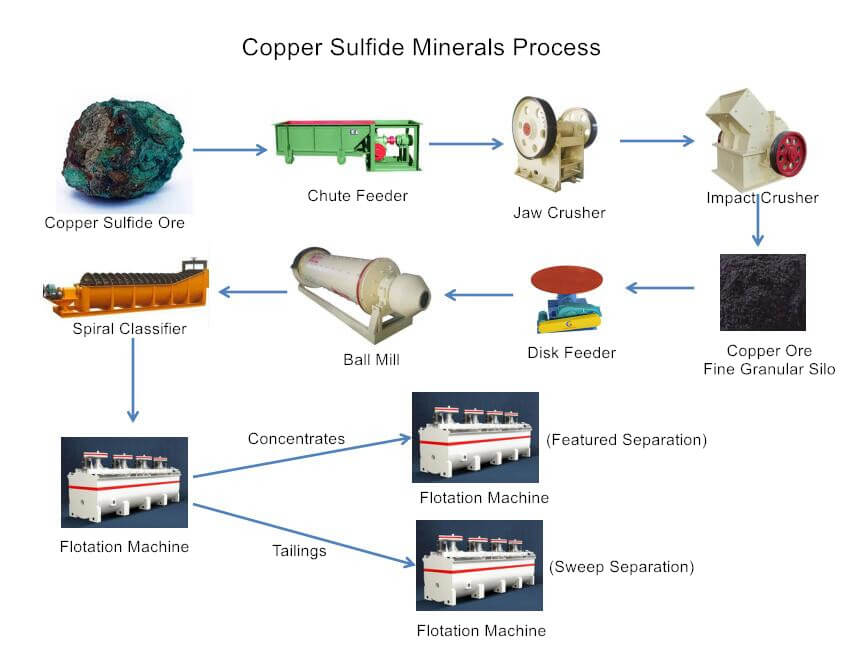

General Process of Copper Sulfide Ore Flotation

According to different useful components, we can divide copper sulfide ore into the following categories: Single copper mineThe ore is relatively simple, and copper is the only valuable component. Gangue is mainly quartz, silicate, and carbonate. Copper-sulfur oreIn addition to copper minerals, we can recover iron sulfide minerals from copper-sulfide ores.

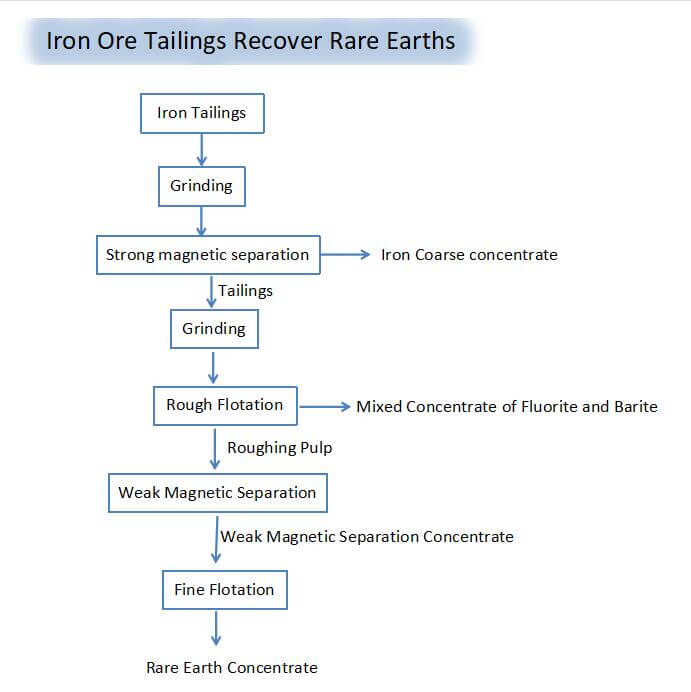

Rare Earth Tailings Recovery

Rare earth tailings are waste or by-products produced during rare earth mines’ mining and extraction process. It mainly contains rare earth elements that cannot be extracted from rare earth ores and other non-rare earth components, such as quartz, limestone, etc. Rare earth tailings usually exist in solid or semi-solid form and have

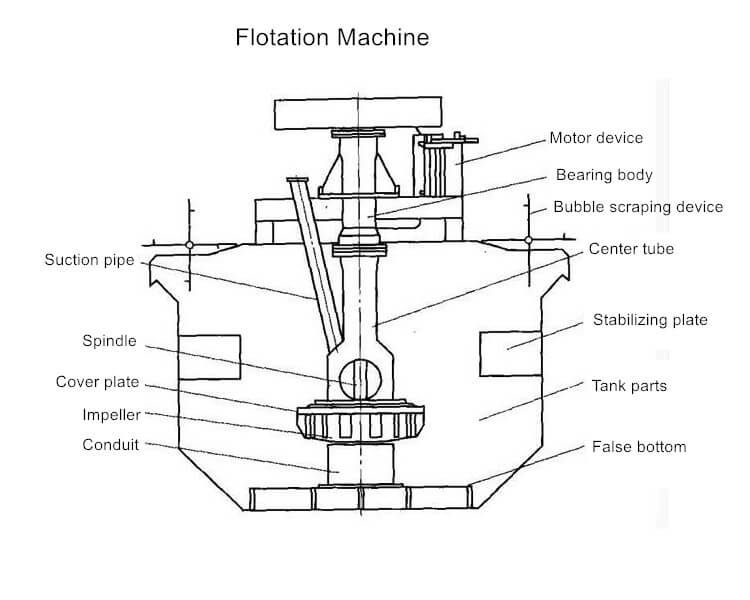

Flotation Machine Main Components And Their Functions

The flotation machine is used for mineral processing. The ore slurry is doped, stirred, aerated, and mineralized through a preprocessor so that some of the mineral particles are selectively fixed on the bubbles; they float to the surface of the slurry and are scraped out to form foam products. It

Magnetic Separator Basic Introduction & How To Choose

A magnetic separator is a device that uses a magnetic field to separate ferrous objects from nonferrous objects. It is commonly used in ore extraction, waste treatment, food processing and other industries. Following we will introduce it to you and discuss how to choose it. How Does The Magnetic Separator Work? Magnetic separators typically

Double Helix Ore Washer: Key Equipment to Improve Ore Washing Efficiency

Double Helix Ore Washers are essential in ore processing operations as they help improve the quality of ores by removing contaminants. They find applications in various mining and mineral processing operations where the purification of ores is necessary to meet quality standards and downstream processing requirements. The spiral washing machine is mainly

Ball Mill Steel Balls: Quality And Gradation

The ball mill steel ball is the medium for grinding materials in the ball mill equipment. The friction and friction between the steel balls of the ball mill and the material produce grinding and peeling effects. During the operation of the ball mill, whether the gradation of the steel balls in

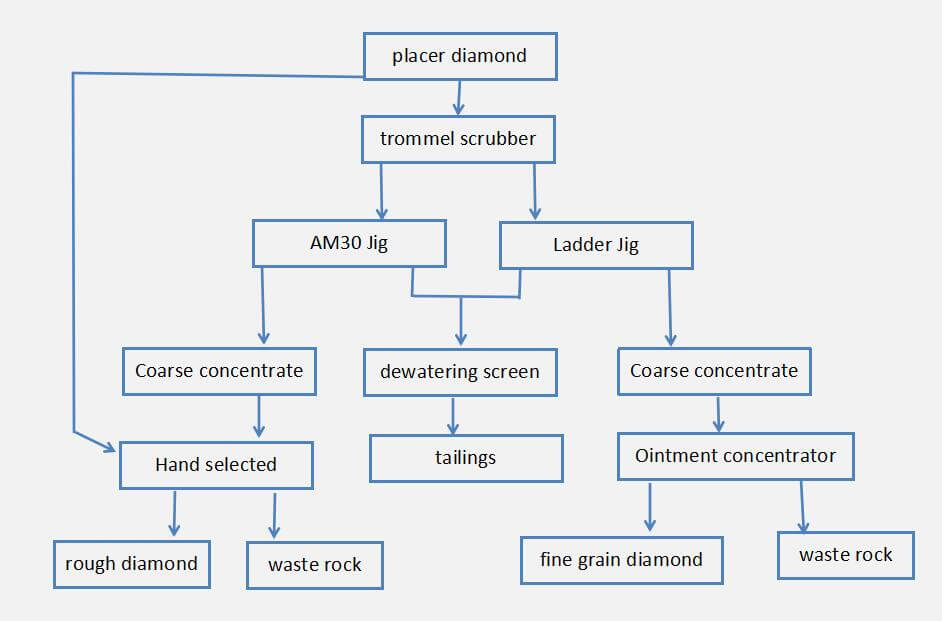

Diamond Process With Jig Separator

Diamond refers to polished diamond. Diamond is a natural mineral and the raw stone of diamond. A diamond is a simple crystal composed of carbon formed under high pressure and high-temperature conditions deep in the earth. As a mineral resource, the market price of diamond is indeed high, but the

Causes & Preventive Measures For Belt Conveyor Breakage

Belt conveyors are widely used in all walks of life due to their advantages of strong transportation capacity, high tensile strength, soft belt body, long life, and good economy. However, due to the influence of many factors, belt breakage in belt conveyors has become a common accident. Once a belt