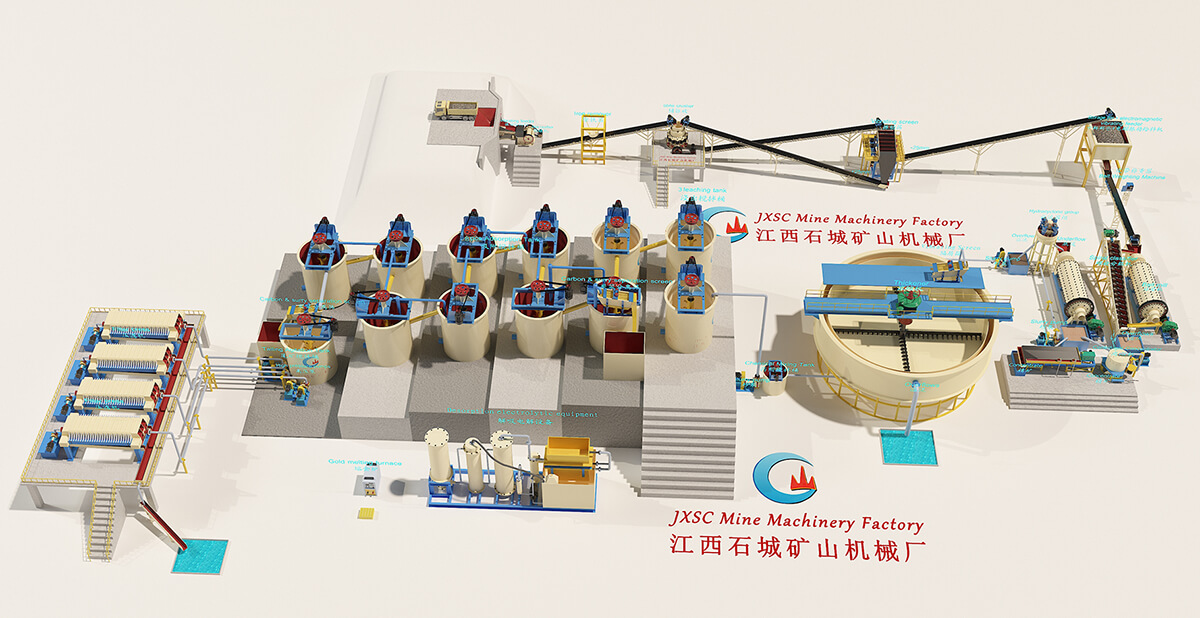

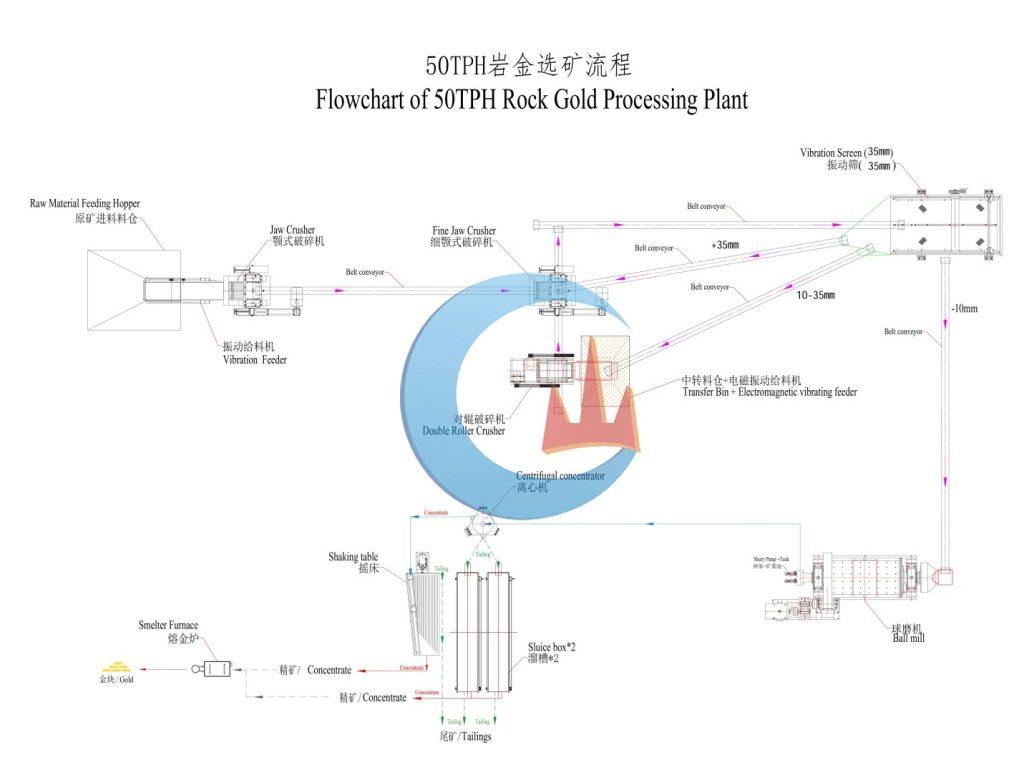

JXSC has provided a successful 50TPH rock gold processing plant in Malaysia. We designed the ore process plant flowchart and plant layout drawing according to the ore conditions. We provided a complete set of plant machines to the mine site and dispatched an engineer to provide on-site installation guidance.

EPCS

Engineering, Procurement & Construction Services

Case Study: Rock Gold Processing Project

Project Overview

Minerals

Rock Gold Ore

Capacity

50 TPH

Feed Size

<250 mm

Location

Malaysia

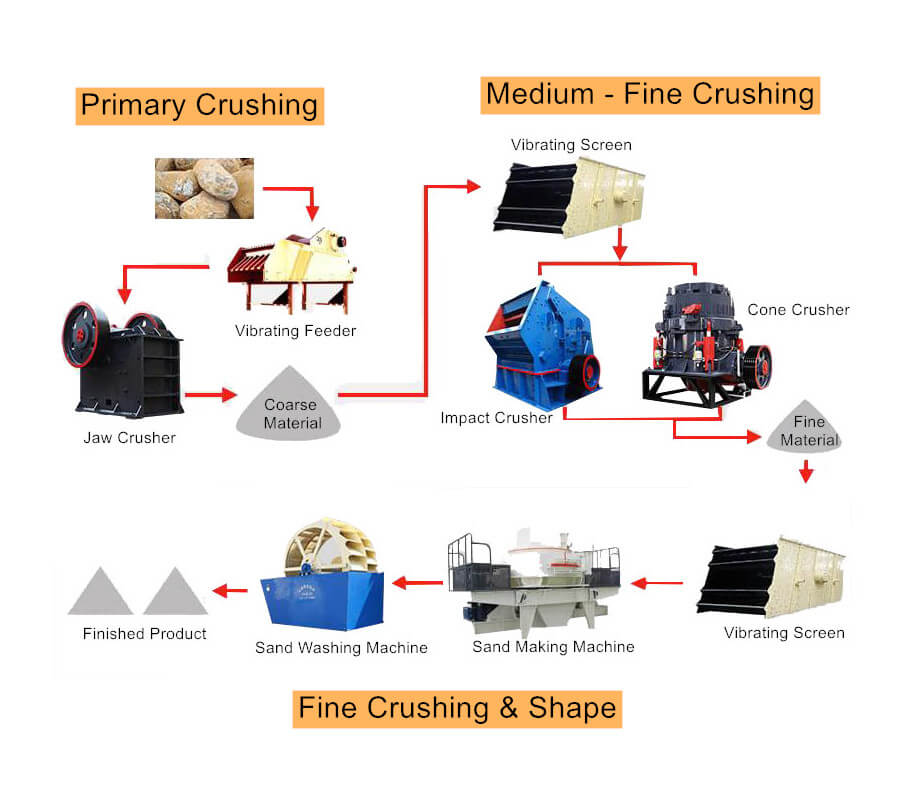

Project Process

Solutions & Process

Rock Gold Processing Plant in Malaysia

This setup is a 50TPH rock gold processing plant, comprising a vibration feeder, jaw crushers, roller crusher, vibrating screen, ball mill, gold centrifugal concentrator, shaking table, sluice box, slurry pump, water pumps, belt conveyors, and gold smelting furnace.

This system is complete from feeding raw gold ore to get the final gold bar.

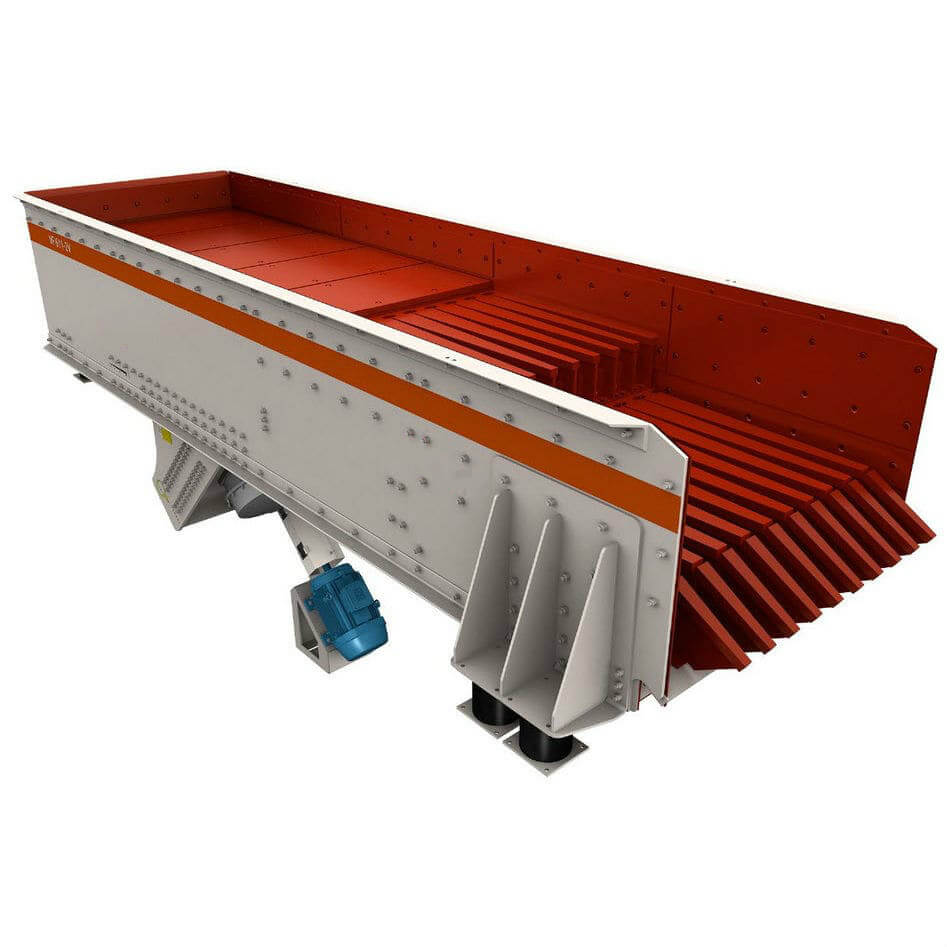

1. Feeding System

- Raw ore is uniformly fed via a vibrating feeder

- Equipment: Vibrating Feeder(DN380*96) with 100mm grizzly gap

2. Primary Crushing

- A jaw crusher reduces ore to an initial size

- Robust construction for hard rock processing

3. Secondary Crushing

- Fine jaw crusher further reduces particle size

- Creates a more uniform feed for screening

4. Primary Screening

- Double-deck vibrating screen separates material into:

• 0-10mm (direct to grinding)

• 10-35mm (for tertiary crushing)

• >35mm (returned to secondary crusher)

5. Tertiary Crushing

- Double roller crusher processes 1a 0-35mm fraction

- Reduces material to 0-6mm specification

- Wear-resistant rollers for extended service life

6. Secondary Screening

- Closed-circuit system with vibrating screen

- Ensures all material meets required sizing

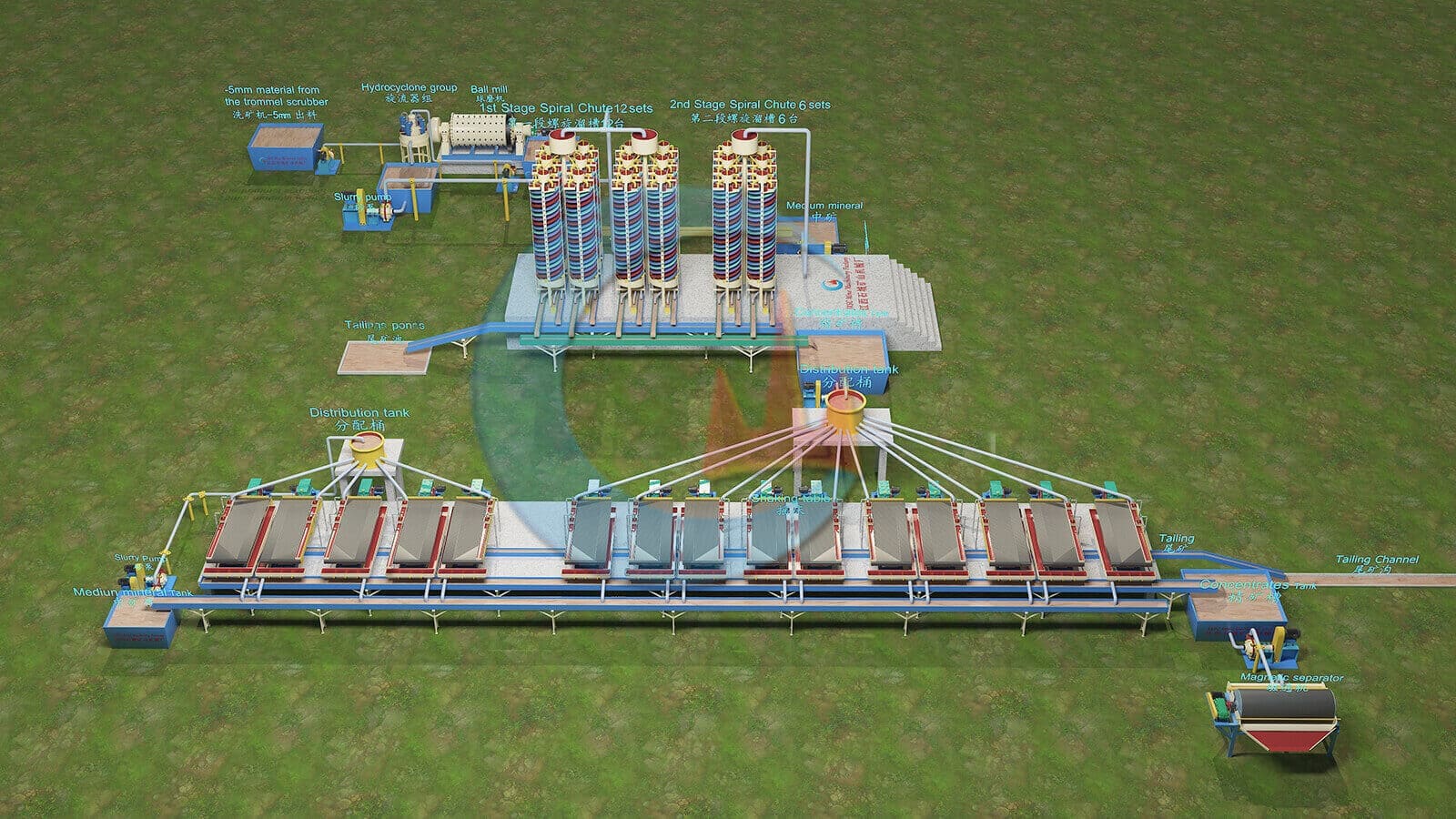

7. Grinding Process

- Ball mill grinds 0-10mm material to 30 mesh

- Continuous operation with controlled slurry density

- Adjustable grind size for optimal liberation

8. Gravity Separation System

A. Primary Recovery:

- Centrifugal concentrator processes 30 mesh slurry

- Produces primary gold concentrate

- Tailings report to secondary recovery

B. Secondary Recovery:

- Sluice box processes centrifugal tailings

- Catches remaining free gold particles

- Dual recovery ensures maximum yield

9. Gold Refining

- Shaking table upgrades centrifugal concentrate

- Produces high-grade smelter feed

- An electric smelting furnace produces pure gold bars

- Final purity typically exceeds 95%

Related Cases

We are a leading provider of innovative and efficient mining equipment and solutions. With years of experience in the industry, we specialize in designing and manufacturing high-quality machines tailored for various mineral processing needs, including gold, diamond, copper, tin, manganese, chrome, titanium, and other ore separations. Our commitment to technology and customer satisfaction drives us to deliver customized solutions that enhance productivity and ensure environmentally sustainable practices. Explore our extensive portfolio of successful case studies and discover how JXSC can transform your mining operations, helping you maximize your profitability while minimizing your ecological footprint. Choose Us—where technology meets efficiency in the world of mining!