Home » Equipment » Washing Equipment » Attrition Cells / Scrubbers

Attrition Cells / Scrubbers

Attrition Cells(Scrubbers) are suitable for industries that require high-concentration grade, such as quartz sand, ceramic raw materials, kaolin, silica sand, iron ore, titanium ore, and spodumene.

Max Feeding Size: 5 mm

Volume: 1-12 m³

Feeding Density: 50%-60%

Application Scope: It is suitable for natural or artificial sand with a mineral particle size of 0-5 mm. It is used for dispersing the slime and removing the impurities on the mineral surface.

Attrition Cells / Scrubbers Overview

Attrition scrubbers, also called attrition cells, are mainly used to disperse mineral sludge and remove impurities on the mineral surface. They are especially suitable for scrubbing quartz sand to improve its quality. The high-efficiency attrition scrubber washing machine can scrub and purify various loose mud granular structure minerals or materials and disperse and dissociate muddy materials. It can effectively remove solvents and soil adhered to the surface of minerals. It has impact resistance, corrosion resistance, and long service life. Features include a low long-term failure rate.

Attrition scrubbers are widely used in the ore processing industry, especially in wet processing processes. They can remove impurities from particles such as diatomaceous earth, iron ore, phosphate rock, coal gangue, etc.

We can adjust the design of this equipment to meet specific processing needs based on the type of particles processed and the throughput. We also design single- and multiple-cell attrition scrubber units for minerals with different scrubbing requirements.

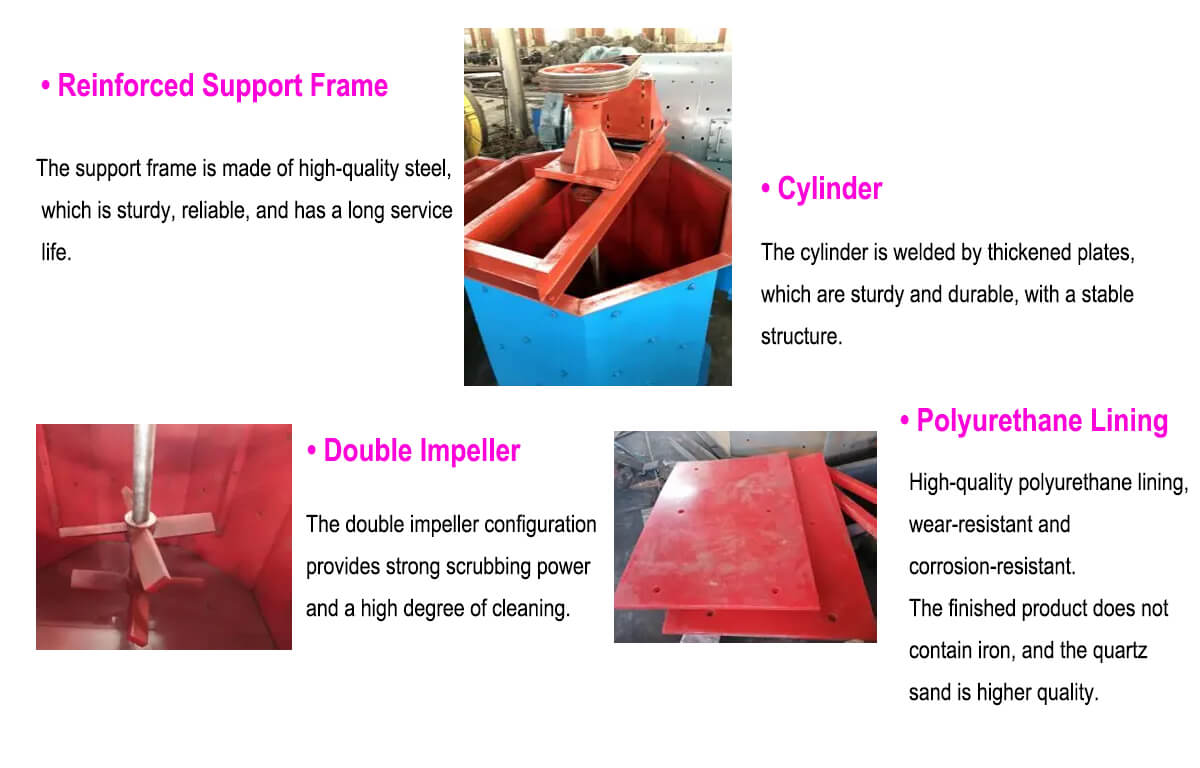

Our Attrition Cells Details

- Reinforced Support Frame

The support frame is made of high-quality steel, which is sturdy, reliable, and has a long service life.

- Cylinder

The cylinder is welded by thickened plates, which are sturdy and durable, with a stable structure.

- Double Impeller

The double impeller configuration provides strong scrubbing power and a high degree of cleaning.

- Polyurethane Lining

High-quality polyurethane lining, wear-resistant and corrosion-resistant. The finished product does not contain iron, and the quartz sand is higher quality.

Advantages

Attrition Cells / Scrubbers Advantages

- The main shaft rotates at high speed, driving the impeller to scrub the material vigorously, with a good scrubbing effect.

- The impeller is located above the “slurry sedimentation area.” It is easy to start and has low starting power, greatly reducing the operator’s labor intensity.

- Simple structure, large effective volume, and small floor space.

- Low peripheral speed and long service life.

- The relative positions of the ore feeding, discharging, and motor of the double-tank scrubbing machine can be manufactured in different positions according to the user’s requirements.

Structures & Working Principle

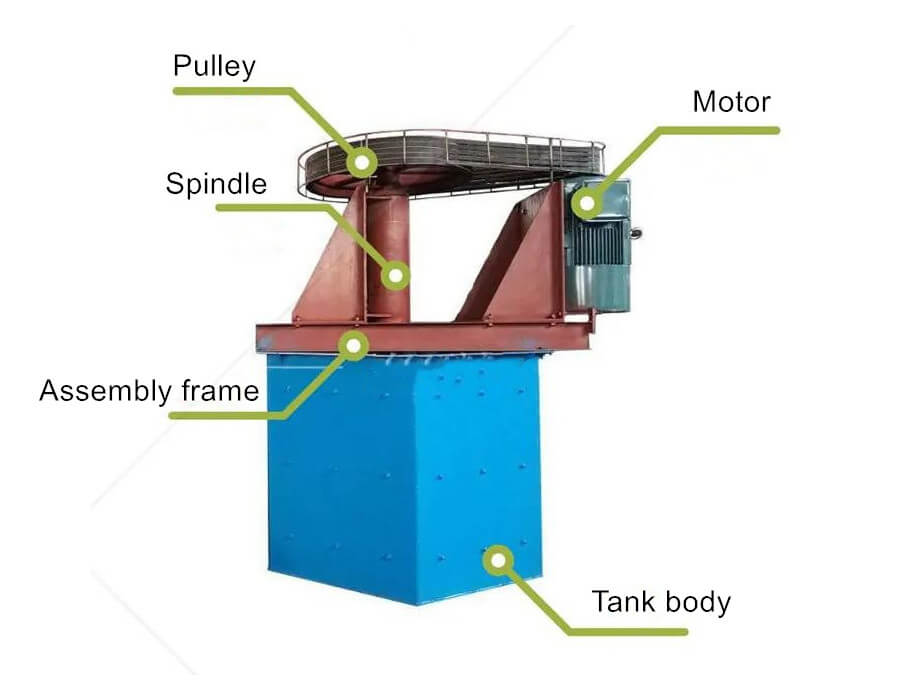

Attrition Cells / Scrubbers Structure

The attrition cell consists of a tank, impeller system(upper, middle, and lower impellers), and drive system(motor and reducer). Generally, the tank is PE-lined and can be either square or octagonal. The impeller system is PE-coated and normally consists of two sets of impellers with opposing pitchers.

Attrition Cells / Scrubbers Working Principle

The motor drives the main shaft to rotate through the pulley (clockwise when viewed from top to bottom), and the blades generate a negative pressure area. The materials are thoroughly stirred and washed as they pass by, and then pushed out by the blades, they flow along the barrel wall. As the materials continue to be fed, they pass through the scrubbed material and will be continuously discharged from the discharge port to complete the scrubbing work.

Technical Parameters

| Model | Volume(m³) | Feeding Size(mm) | Feeding Density(%) | Motor Power(kw) | Dimension L*W*H(mm) | Weight(kg) |

| GSC1-1 | 1 | ≤5 | 50-60 | 11 | 1420x1310x1860 | 1300 |

| GSC1-2 | 2 | ≤5 | 50-60 | 11×2 | 2340x1310x1860 | 2500 |

| GSC2-1 | 2 | ≤5 | 50-60 | 30 | 2150x1900x2780 | 3200 |

| GSC2-2 | 4 | ≤5 | 50-60 | 30×2 | 3530x1900x2780 | 5300 |

| GSC4-1 | 4 | ≤5 | 50-60 | 55 | 2596x2800x3441 | 3800 |

| GSC4-2 | 8 | ≤5 | 50-60 | 55×2 | 4430x2800x3441 | 7500 |

| GSC6-2 | 12 | ≤5 | 50-60 | 90×2 | 4900x3200x4100 | 9500 |