Home » Equipment » Crushing & Screening Equipment » Roller Crusher

Roller Crusher

The double roll crusher is a highly efficient crushing equipment for medium to fine crushing of soft to medium hard materials. It is particularly suitable for crushing brittle materials (such as coal, coke, limestone, slag, etc.) and can achieve precise particle size control.

Capacity: 2-140 TPH

Feeding Size: <150mm

Discharge Size: 2-50m

Process Material: River pebble, granite, basalt, iron ore, limestone, quartz, gangue, and so on.

Roller Crusher Overview

The Doule Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crushing the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, and chemical materials.

Roller Crusher Types

According to the number of rolls, the roll crushers can be divided into single-roll crushers, double-roll crushers, and four-roll crushers. A double-roll crusher is the most used type. We produce industrial roller crushers and the laboratory uses a small roll crusher.

Advantages

The roller crusher offers outstanding durability with its wear-resistant lining, ensuring a long service life and simple maintenance. Its compact, lightweight design requires minimal space while delivering impressive production capacity, making it a space-saving and cost-effective investment for crushing operations. The adjustable discharge opening allows precise control over material size, while its high reduction ratio, low vibration, and effective dust removal contribute to quieter, cleaner performance. Engineered for efficiency, it delivers uniform, well-shaped granules with low energy consumption, making it a reliable, high-performance solution for a wide range of crushing applications.

✔ Extrusion crushing: The two rollers rotate in opposite directions, and the materials are compressed, sheared, and crushed between the two rollers.

✔ Uniform and controllable particle size: The roller spacing is adjustable (1-20mm), which can accurately control the particle size of the discharged material.

✔ Low over-crushing rate: Compared with hammer crushing and impact crushing, less powder is produced.

✔ Adaptable to brittle materials: Suitable for fragile materials such as coal, coke, gypsum, etc.

✔ Easy maintenance: Simple structure, easy replacement of roller skin, and low operating cost.

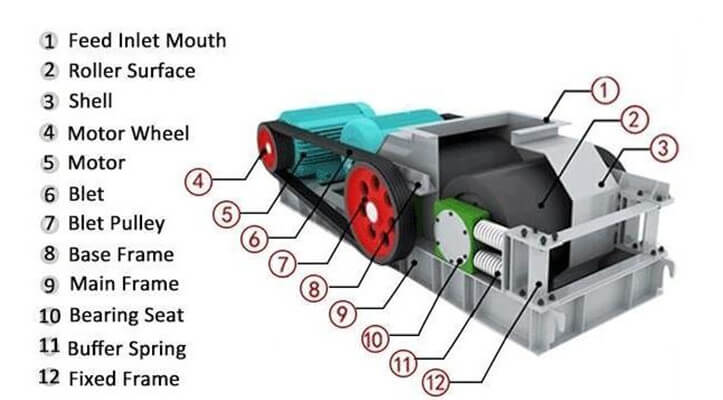

Structures & Working Principle

Double Roller Crusher Structure

The main parts of a roller crusher are bearing box, roll shell, bearing housing, adjusting rod, motor, carrier, fixed roller, movable roller and safety spring, etc.

Double Roller Crusher Working Principle

The roller of the roller crusher is supported by the spring pressure. Under normal working conditions, the spring force is sufficient to overcome the crushing force of the crushed material. By changing the number of spacers between the frame and the movable bearing, the width of the discharge port between the two rolls can be adjusted to adjust the grain size.

When there is a material that cannot be broken into the crushing chamber, the spring is compressed, and the movable roller is retracted to increase the discharge opening. After the material is discharged, the movable roller is reset under the spring pressure.

Technical Parameters

| Model | Rotar Size | Feed Size(mm) | Discharge Opening Range (mm) | Capacity(T/H) | Power(kW) | Overall Dimension (mm) |

| 2PG400*250 | Ⴔ400*250 | <25 | 1-20 | 1.5-10 | 5.5*2 | 3080*1260*780 |

| 2PG610*400 | Ⴔ600*400 | <35 | 1-20 | 5-20 | 15*2 | 3650*1540*960 |

| 2PG800*600 | Ⴔ800*600 | <40 | 2-30 | 15-30 | 22*2 | 4250*2000*1200 |

| 2PG800*800 | Ⴔ800*700 | <40 | 2-30 | 20-40 | 30*2 | 4250*2100*1250 |

| 2PG1000*800 | Ⴔ1000*800 | <50 | 2-40 | 35-70 | 45*2 | 4900*3250*1310 |