Home » Equipment » Dewatering Equipment » Thickener

Thickener

A thickener is a solid-liquid separation device widely used in industries such as mining, metallurgy, and environmental protection, primarily for the concentration and clarification of suspensions.

Capacity: 1.3-1440 t/d

Application: Metallurgy, chemical, coal, non-metal ore dressing, environmental protection, and other industries.

Thickener Overview

The thickener is applicable to concentrate and tailings dewatering treatment in mining applications, widely used in metallurgy, the chemical industry, coal, non-metallic mineral processing plants, environmental protection, and other industries. The high-efficiency mining thickener is not a gravity separation equipment, but a piece of dewatering equipment combined with characteristics of mud filtration.

A good concentrator settling process must have three stages that are not in short supply. These are the stage of coagulation and destabilization, the stage of coagulation and granulation, and the stage of filtration and compression. However, the realization of these three stages must have certain equipment to ensure that the flocculation reaction cannot be sufficient, and the effect of solid-liquid separation is impossible to achieve the desired state.

As the large flocs gather more and more, the ideal dense phase layer at the bottom of the deep cone concentrator is formed. In the upper part of the dense phase layer, thicker and less stable flocs are deposited, which are essentially a floating filter medium that has a very beneficial intercepting effect on small particles that escape with the upflow. The sediment at the bottom of the dense phase layer, under the combined action of the larger head and the material gravity, can obtain a large pressure in the bottom stream of the deep cone concentrator, so that the concentration of the material to be discharged is greatly improved.

Advantages

The thickener significantly enhances sedimentation efficiency through multiple advanced mechanisms: By adding flocculants to increase solid particle size, it dramatically accelerates settling speed, while strategically installed inclined plates simultaneously shorten particle settlement distance and expand the effective settling area. This innovative configuration fully leverages principles of flocculation, filtration, and compression to optimize the mud deposition process, significantly boosting treatment capacity in the thick phase layer. Complemented by comprehensive automatic control systems, the thickener delivers precise, high-performance operations with minimal manual intervention—making it an exceptionally efficient solution for slurry concentration and dewatering applications.

Key Advantages of Thickeners

1. Efficient Solid-Liquid Separation

- Uses gravity sedimentation to quickly separate solid particles (e.g., ore fines, sludge) from liquids, achieving high underflow density (30%-70%) and clear overflow water.

- High processing capacity, making it ideal for large-scale industrial operations, such as processing thousands of tons of tailings daily in mines.

2. Compact Design, Saves Space

- Compared to traditional sedimentation tanks, thickeners utilize a vertical settling design, reducing footprint by over 50% for the same processing capacity.

- Ideal for mines or factories with limited space.

3. Low Energy Consumption & Operating Costs

- Primarily relies on natural sedimentation, with power mainly used for raking mechanisms (small units require only a few kW), making it 50% more energy-efficient than centrifuges or filter presses.

- Low maintenance, with long-lasting components (e.g., rakes can last years without replacement).

4. Strong Adaptability

- Can process fine particles (e.g., -200 mesh slurry) and even colloidal sludge.

- Adding flocculants (e.g., polyacrylamide, PAM) significantly improves sedimentation speed, handling highly viscous or slow-settling materials.

5. High Automation

- Modern thickeners come with automated control systems, monitoring mud bed thickness and underflow density in real time, adjusting discharge rates, and reducing manual intervention.

- Some models support remote monitoring, aligning with smart mine requirements.

6. Environmental & Resource Recovery

- Overflow water can be recycled (e.g., in mineral processing), reducing water usage and wastewater treatment costs.

- Higher underflow density reduces load on downstream dewatering equipment (e.g., filter presses), improving overall efficiency.

Structures & Working Principle

Thickener Structure

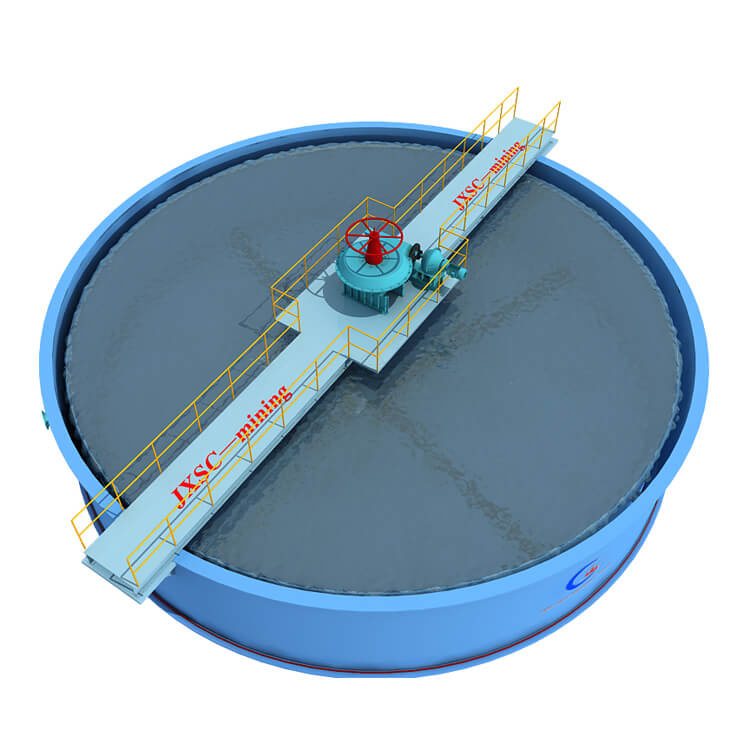

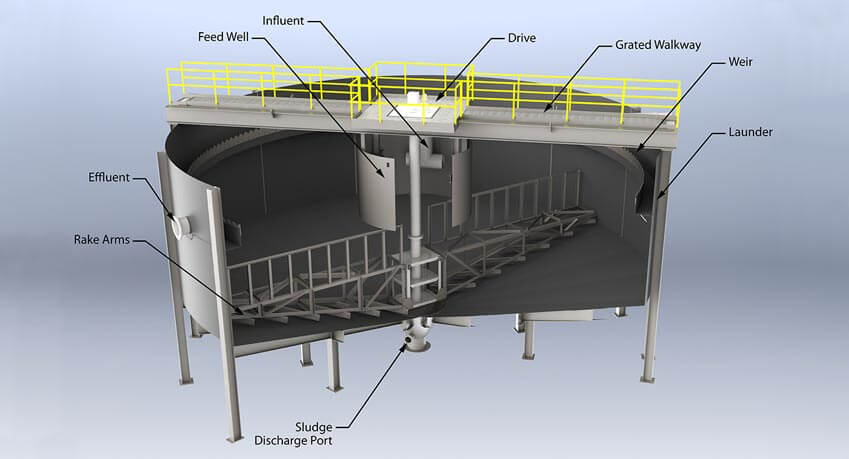

The thickener (high-efficiency thickener) generally consists of a thickener tank, a truss, a transmission, a truss lifting device, a feeding device, a discharging device, and a signal safety device.

Thickener Working Principle

The main feature of the concentrator (high-efficiency concentrator) is to add a certain amount of flocculant to the slurry to be concentrated, so that the ore particles in the slurry form floccules, accelerate the sedimentation speed, and thereby achieve the purpose of improving the concentration efficiency.

Technical Parameters

| Center Drive Thickener Technical Parameters | |||||||

| Model | Thickener Tank | Sedimentation Area (m2) | Transmission Speed (r/min) | Motor | Capacity (t/d) | ||

| Diameter (m) | Depth (m) | Model | Power (kw) | ||||

| NZS1 | 1.8 | 1.8 | 2.55 | 0.5 | Y90L-6 | 1.1 | 1.3-5.6 |

| NZS2.5 | 2.5 | 1.8 | 4.9 | 0.33 | Y90L-6 | 1.1 | 5-10.8 |

| NZS3.6 | 3.6 | 1.8 | 10.2 | 0.38 | Y90L-6 | 1.1 | 5-22.4 |

| NZS6 | 6 | 2.956 | 28 | 0.35 | Y90L-4 | 1.5 | 14-60 |

| NZS8 | 8 | 3 | 50.2 | 0.27 | Y132S-6 | 3 | 25-120 |

| NZS9 | 9 | 3 | 63.5 | 0.25 | Y132S-6 | 3 | 32-150 |

| NZS12 | 12 | 3.6 | 113 | 0.19 | Y132S-6 | 3 | 50-250 |

| NZS15 | 15 | 3.6 | 176 | 0.1 | Y132M2-6 | 5.5 | 70-350 |

| NZS18 | 18 | 3.74 | 255 | 0.2 | Y160M-6 | 7.5 | 100-560 |

| NZS20 | 20 | 4.4 | 315 | 0.2 | Y160M2-8 | 7.5 | 200-1440 |

| NZS24 | 24 | 4.716 | 452 | 0.1 | Y180L-8 | 11 | 200-1440 |

| Peripheral Rack Drive Thickener Technical Parameters | |||||

| Model | Thickener Tank | Sedimentation Area (m2) | Motor Power (kw) | Capacity (t/d) | |

| Diameter (m) | Depth (m) | ||||

| NT-15 | 15 | 3.5 | 177 | 5.5 | 1.3-5.6 |

| NT-18 | 18 | 3.5 | 255 | 5.5 | 5-10.8 |

| NT-24 | 24 | 3.7 | 452 | 7.5 | 5-22.4 |

| NT-30 | 30 | 3.6 | 707 | 7.5 | 14-60 |

| NT-45 | 45 | 5.06 | 1590 | 11 | 25-120 |

| NT-50 | 50 | 4.524 | 1964 | 11 | 32-150 |

| NT-53 | 53 | 5.07 | 2202 | 11 | 50-250 |