Home » Equipment » Flotation Equipment » JJF Flotation Cell/Machine

JJF Flotation Cell/Machine

Capacity: 2~20m³/min

Process Material: Non-ferrous metal, black metal, and nonmetal minerals.

JJF flotation machine is an air self-suction mechanical stirringfloatation cell without slurry suction.

JJF Flotation Cell/Machine Overview

Flotation machines constitute the basic equipment for useful minerals recovery from non-ferrous ores and other raw materials by flotation. They can operate also as individual flotation cells.

Flotation Cells (Froth Flotation) were developed to separate and recover high-value Sulphide ores from low-grade ore bodies. The Flotation Cell is aerated to produce bubbles and agitated to keep the solids particles in suspension in the pulp. A flotation cell is an appliance in which froth flotation of ores is performed. It has provisions for receiving conditioned pulp, aerating this pulp, and for separate discharge of the resulting mineralized froth and impoverished tailings.

Flotation Cells/Machines Types

- Agitating flotation machine

- Self-priming flotation machine

- Aeration flotation machine

- Flotation column machine

Flotation Cells/Machines For Sale

Our froth flotation separation is sold all around the world and is popular with clients. The models of our flotation cells are main including SF, XJK, JJF, XCF, and KYF flotation cells.

Advantages

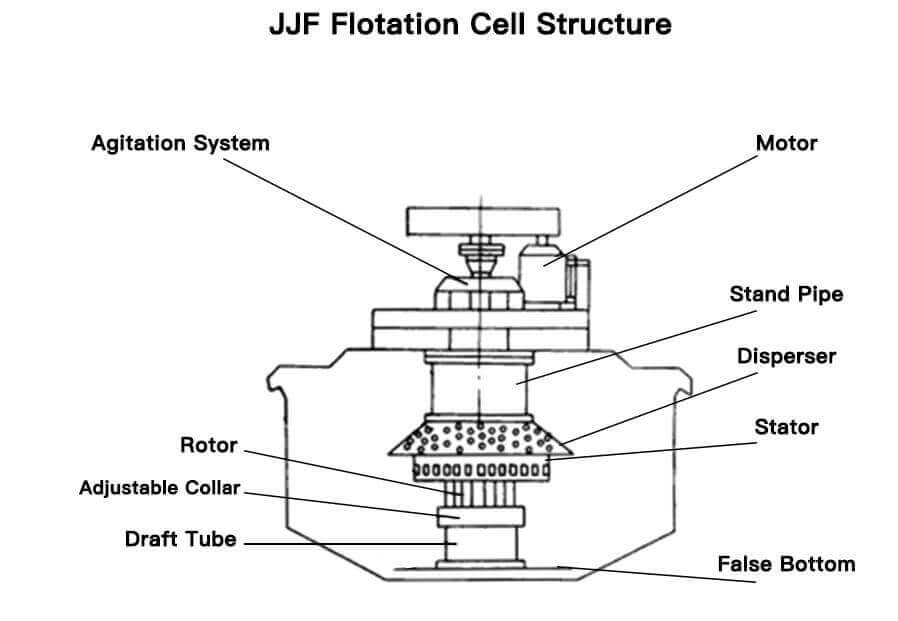

The JJF flotation cell offers several key advantages for efficient mineral separation: Its low power consumption is ensured by the small-diameter, low-speed rotor, while the large clearance between rotor and disperser minimizes wear. The cylindrical stator with an oval hole enhances air-pulp mixing, and the low stator height allows high slurry circulation (up to 2.5x), improving ore mineralization, reagent dispersion, and air mixing.

Featuring an umbrella-shaped perforated stator, it stabilizes the froth layer by preventing vortex interference. With high air inflation and superior dispersion, it ensures efficient coarse particle recovery due to reduced froth travel distance and a beveled tank bottom that prevents sedimentation. The wide particle size range and high recovery rate are further enhanced by the elevated rotor position, avoiding contact with abrasive oversize materials.

As a self-inflation (non-self-priming) mechanically agitated cell, it easily integrates with the SF flotation cell in a combined unit—serving as the straight tank while the SF acts as a suction tank—for optimized flotation performance.

Six Core Advantages

1. Deep trough advantage

- Extended slurry residence time of 3.5-5 minutes (XJK only 2-3 minutes)

- Especially suitable for difficult-to-separate ores with complex particle size distribution

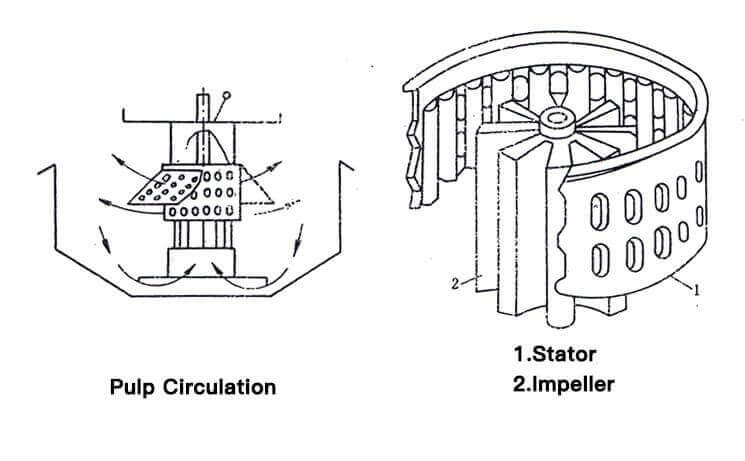

2. Dual circulation system

- Axial flow: Ensures suspension of coarse particles

- Radial flow: Enhances mineralization of fine particles

3. Energy-saving performance

- Power consumption per ton of ore is 1.1-1.8 kW·h (25% lower than XJK for the same processing capacity).

4. Large space for intelligent transformation

- Reserved mounting area for inverter interface and foam thickness sensor.

5. Easy maintenance

- Modular quick-release rotor design, replacement time less than 4 hours.

6. Combination unit compatibility

- Can be combined with the SF type for a combined self-priming and aeration process.

Structures & Working Principle

JJF Flotation Cell/Machine Structure

JJF Flotation Cell/Machine Working Principle

When the JJF mechanical agitation flotation machine is working, the rotor creates a fluid vortex inside the standpipe and the draft tube and causes a sufficient vacuum area to induce air into the standpipe through the air inlet duct. The induced air is mixed with pulp between the impeller and stator. The mixture of air and pulp will have a tangential movement as a result of the impeller. But when the Mineralized Bubbles pass through the pores on the stator, they change to a radial motion until they bump into the Disperser and are separated evenly. When the Mineralized Bubbles rise up to the froth zone, the scraper revolves to discharge the products.

Technical Parameters

| Model | Volume(m3) | Cell size(mm) | Impeller Dia.(mm) | Impeller speed(r/min) | Capacity(m3/min) | Power for Stir/Scraper(kw) | Singe cell weight(kg) |

| JJF-1 | 1 | 1100*1100*1000 | 280 | 0.3-1 | 5.5/1.5 | ||

| JJF-2 | 2 | 1400*1400*1150 | 280 | 0.5-2 | 7.5/1.5 | ||

| JJF-3 | 3 | 1500*1850*1200 | 350 | 1-3 | 11/1.5 | ||

| JJF-4 | 5 | 1600*2150*1250 | 410 | 305 | 2.0-4 | 11/1.5 | 2303 |

| JJF-5 | 5 | 1600*2150*1550 | 410 | 305 | 2.0-6 | 11/1.5 | 2416 |

| JJF-8 | 8 | 2200*2900*1400 | 540 | 233 | 4.0-12 | 22/2.2 | 4507 |

| JJF-10 | 10 | 2200*2900*1700 | 540 | 233 | 5.0-10 | 22/1.5 | 4820 |

| JJF-16 | 16 | 2850*3800*1700 | 700 | 180 | 5.0-16 | 37/1.5 | 7657 |

| JJF-20 | 20 | 2850*3800*2000 | 770 | 180 | 5.0-20 | 45/1.5 | 8505 |