High-Performance & Reliable Rock Crushers For Mining & Aggregates

— Explore JXSC’s durable crushers designed for various ores and capacities, backed by decades of experience and global support.

Find Your Ideal Rock Crusher Machines

Jaw Crusher

The ultimate solution for primary crushing of hard and abrasive materials. Robust and reliable first-stage size reduction.

Key Specs:

Capacity Range: 1-1120 tph

Feeding Size: <1200 mm

Output Size: 10-360 mm

Applicable Materials: Granite, basalt, quartzite, iron ore, concrete.

Cone Crusher

Secondary/tertiary crushing with high efficiency and low wear cost. Ideal for medium-hard to hard materials.

Key Specs:

Capacity Range: 10-1450 tph

Feeding Size: <425 mm

Output Size: 6-64 mm

Applicable Materials: Limestone, river pebble, diabase, copper ore.

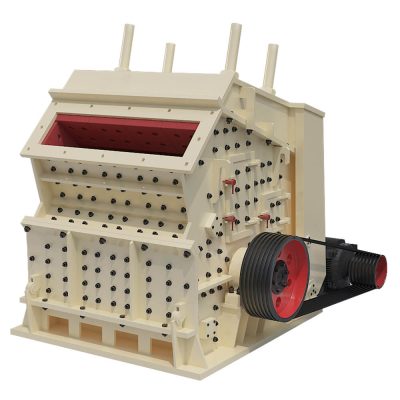

Impact Crusher

Primary/secondary crushing for softer materials, delivering excellent cubic shape output.

Key Specs:

Capacity Range: 30-500 tph

Feeding Size: <700 mm

Output Size: 5-60 mm

Applicable Materials: Limestone, gypsum, coal, recycled concrete.

Hammer Crusher

Efficiently crushes brittle, medium-hard materials like limestone, coal, and gypsum.

Key Specs:

Capacity Range: 1-110 tph

Feeding Size: <350 mm

Output Size: <35 mm

Applicable Materials: Coal, salt, chalk, brittle minerals.

Mobile Crusher Plant

Flexible and versatile crushing solutions designed for optimal site mobility and quick setup.

Key Specs:

Mobility: Wheeled / Tracked

Main Crusher: Jaw, Cone, Impact

Vertical Shaft Impact Crusher

The ultimate solution for high-quality cubical aggregate shaping and fine crushing. Ideal for producing precisely graded sand, manufactured sand (M-Sand), and high-efficiency tertiary/final-stage crushing.

Need More Rock Crusher Options?

Explore our full range or contact us for specialized crushing needs.

Versatile Applications of Crusher Across Industries

Minerals Processed

- Gold Ore

- Iron Ore

- Copper Ore

- Manganese Ore

- Lead & Zinc Ore

- Coltan & Tin Ore

- Chrome Ore

- Limestone & Dolomite

- Granite & Basalt

- Quartz & Silica Sand

- Construction Waste

Target Industries

- Large-Scale Mining Operations

- Small to Medium-Scale Mining

- Quarrying & Aggregates Production

- Mineral Processing Plants

- Construction & Demolition Recycling

- Road Building Projects

Why Partner With JXSC for Crushing?

Proven Reliability & Durability

Built for the toughest mining conditions with a focus on a 10-15 year operational lifespan. Benefit from our manufacturing expertise since 1985.

Cost-Effective & Efficient

Optimized crushing chambers and energy-efficient designs reduce operational costs while maximizing throughput and product quality.

Full Process Integration

Our crushers seamlessly integrate into complete mineral processing lines, compatible with JXSC feeders, screens, conveyors, and more.

Comprehensive Support & Services

Free Processing Flow Design

Leverage our expertise for a custom-designed crushing circuit tailored to your specific ore and requirements – at no initial cost.

Installation & Commissioning

We offer on-site support for setup and commissioning. Our fixed quotes often include these essential services for a smooth start-up.

Spare Parts & Maintenance

Reliable supply of genuine wear and spare parts to minimize downtime. Maintenance guidance is available.

Reliable After-Sales Service

Access expert technical assistance around the clock, in multiple languages, ensuring your operations run smoothly.

Trusted Performance Worldwide

60+

Countries Served Globally

1000+

Successful Project Cases

Since 1985

Decades of Manufacturing Experience

Limestone Crushing

Country: Cambodia

Capacity: 300 TPH

Primary Crushing: Jaw Crusher

Secondary Crushing: Cone Crusher

Rock Copper Process

Country: Zambia

Capacity: 25 TPH

Crushing: Jaw Crusher

Rock Lead Zinc Ore Process

Country: Morocco

Capacity: 30 TPH

Crushing: Jaw Crusher + Fine Jaw Crusher

Alluvial Gold & Columbite

Country: Brazil

Capacity: 100 TPH

Crushing: Hammer Crusher

Gold CIP

Country: Kenya

Capacity: 300 TPH

Crushing: Jaw Crusher + Fine Jaw Crusher

Tungsten Ore Processing

Country: Korea

Capacity: 20 TPH

Primary Crushing: Jaw Crusher

Granite Crushing

Country: Nigeria

Capacity: 300-400 TPH

Primary Crushing: Jaw Crusher

Secondary Crushing: Impact Crusher

Coltan Processing

Country: Uganda

Capacity: 100 TPH

Crushing: Cone Crusher

Ready to Optimize Your Crushing Operations?

Let our experts help you select the perfect rock stone crusher or design your entire processing plant. Contact us today for a no-obligation consultation and quote.